[ad_1]

New analysis from China exhibits that ultra-narrow connections can enhance the efficiency of natural PV. The scientists constructed an 11.08 cm2 panel with a formidable geometric fill issue of 98%.

A Chinese analysis group has created ultra-narrow interconnections for natural photo voltaic modules utilizing 355-nm ultraviolet nanosecond laser processing. The researchers claimed to have achieved an interconnection width of 80 μm, which till now was solely doable with femtosecond pulse lasers.

“The rising value of Femtosecond pulse lasers and the elevated power consumption could current potential challenges, particularly inside large-scale manufacturing processes,” they mentioned. “This research presents an economical and reproducible methodology to supply high-performance natural photo voltaic cell (OSC) modules.”

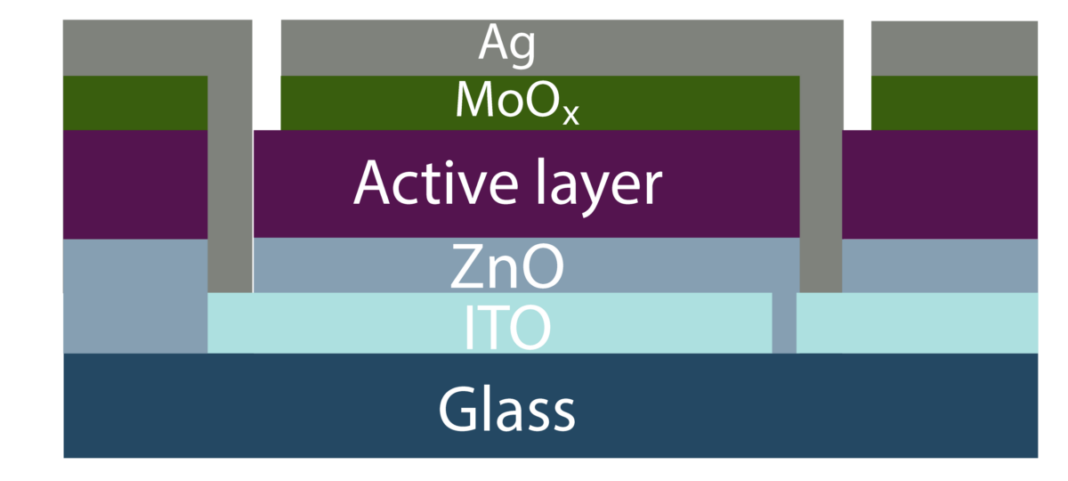

As a consultant case, they selected an OSC system utilizing an indium tin oxide (ITO) skinny movie layer, with zinc oxide (ZnO) because the electron transport layer. The lively layer is made from heterojunction polymer materials PM6:L8-BO:PC61BM, a layer of molybdenum oxide (MoOx), and a metallic contact of silver (Ag). The substrate is predicated on glass.

“The foremost impediment hindering the commercialization of OSCs lies within the problem of rising laboratory-scale cells into giant space modules,” defined the analysis group. “One of the challenges contains getting ready to successfully join the cells to the modules whereas minimizing the lack of effectivity. If the units of enormous space are configured as a big cell as an alternative of being linked in sequence , the strict conductance of clear electrodes, comparable to ITO, results in a lack of sequence resistance, which, in flip, causes a lack of effectivity.

To resolve this situation, a laser writing methodology is usually used to create a mixed sequence connection utilizing P1-P2-P3 patterning. In their analysis, this writing was completed with cheaper nanosecond laser processing.

In the P1 stage, the skinny ITO movie is lower into strips indicating sub-cells. The Q pulse width is optimized to be a continuing of 4.0 μs. In the investigation, the scientists discovered that the spikes produced by this course of don’t cut back the efficiency of the OSC modules.

The subsequent writing step, P2, “is designed to take away all of the layers superimposed on the ITO layer, leaving the ITO intact and thus making an excellent ohmic contact between within the ITO cathode and the Ag anode.”

The scientists discovered that it may be completed with a Q-switched pulse width from 4.5 to six.6 μs, as a result of all of them present the identical outcomes. “Increasing the Q-switched pulse width to 7.7 μs doesn’t consequence within the full removing of the lively layer. As a consequence, it results in a lower in all of the gadget parameters of the module,” they added. “These outcomes clearly show that the P2 course of window will be a lot wider after the advantageous steadiness of the sub-cell width and the laser etching marking depth.”

The purpose of the final step, P3, is to section the Ag movie into separate strips for the dedication of sub-cells. For that, the lecturers utilized two strategies – shallow scribing (P3-S) and deep scribing (P3-D) – and located that in each instances, P3-S and P3-D, the OSC exhibits related efficiency.

“After optimizing the laser parameters for P1, P2, and P3 scribes, a slender sample space was obtained. The interconnection width decreased to about 80 μm, which is probably the most slender width utilizing a nanosecond laser and akin to a femtosecond laser,” they mentioned. “The width of the sub-cell is strategically positioned at 4.1 mm to maximise the module space and obtain a formidable geometric fill issue of 98%, which reaches the benchmark for nanosecond laser-manufactured OSC modules.”

Creating a tool with an space of 1 cm2, the module supplies an influence conversion effectivity of 17.55%. “An effectivity of 16.10% was obtained for an OSC module with an lively space of 11.08 cm2, which is the very best effectivity for natural photo voltaic modules reported to this point,” the group added. “Impressively, the top-performing OSC module achieves an excellent geometrical fill issue of 98%, resulting in a licensed effectivity of 15.43% in an 11.30-cm2 aperture space.”

The novel methodology is offered in “A 16.10% effectivity natural photo voltaic module with ultra-narrow connections made by nanosecond ultraviolet laser processing,” revealed in Cell Reports Physical Science. The group consists of scientists from the Central South University of China, the Chinese Academy of Sciences, the City University of Hong Kong, and the Chinese National Center for Nanoscience and Technology.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].

Popular content material

[ad_2]

Source link