[ad_1]

Chinese scientists evaluated the fracture energy of economic G12 monocrystalline wafers by means of a 4-point bending take a look at and located that the wafer thickness, the place of the silicon wafer on the silicon brick, and the take a look at course of bending are key parameters to develop future methods. aimed toward decreasing fractures.

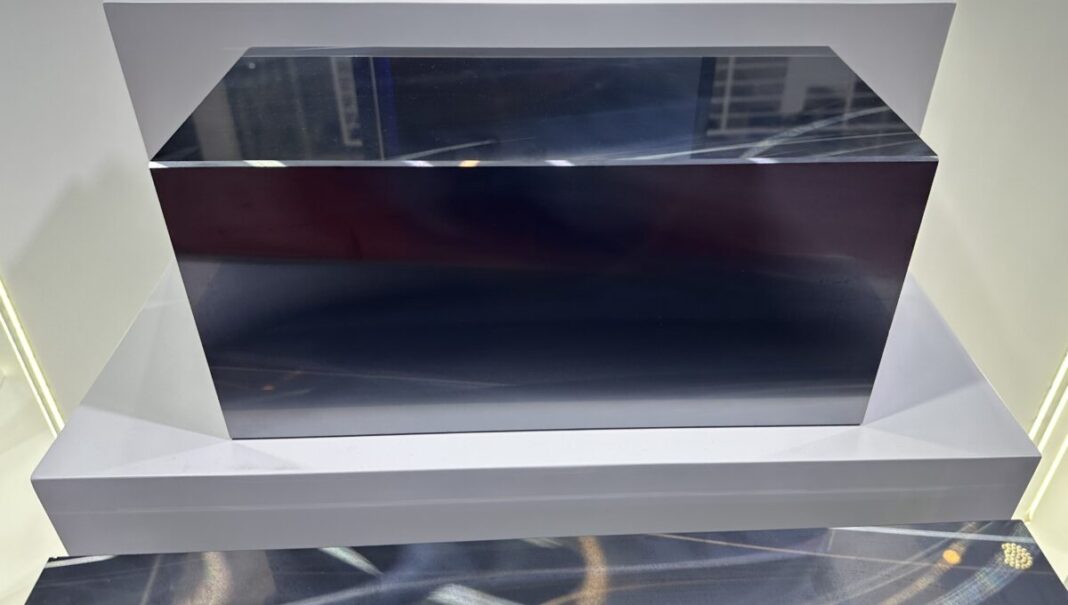

Researchers at Shandong University in China examined the fracture energy of economic 210 mm x 210 mm monocrystalline silicon G12 wafers used for photo voltaic cell manufacturing and located that a number of methods can be utilized to supply massive measurement and ultra-thin silicon wafers whereas minimizing breakage. potentialities in the course of the sawing course of and post-processing.

“We investigated the impact of wafer thickness on the fracture energy and the impact of the place of the silicon wafer on the silicon brick on the fracture energy of the silicon wafer,” the lead creator of the analysis, Yufei Gao, mentioned pv journal. “Four-point bending (PB) assessments have been carried out on three thicknesses of G12 mono-Si wafers, and the load-displacement curves in the course of the take a look at course of have been recorded.”

This kind of take a look at is used to find out the flexural energy of a fabric and its tendency to crack beneath bending load. The materials is normally positioned in two supporting pins and centrally charged in two stress strains with a testing piston.

For their evaluation, the researchers used the finite component technique (FEM), which is a numerical method used to carry out a finite component evaluation (FEA) of any given bodily phenomenon, and the Weibull operate, which is most generally utilized in silicon wafer evaluation. damaged.

“The fundamental assumption of the Weibull operate is the weakest hyperlink assumption: the survival likelihood of a pattern is the product of the survival chances of every quantity component throughout the pattern,” defined the scientists. “Therefore, the fracture energy of silicon wafers is set by the weakest defect.”

They analyzed three totally different thickness wafers of 130 mikrometer140 mikrometerand 150 μm and contemplating the place of the silicon wafer on the silicon brick and the course of the bending take a look at.

The evaluation confirmed that the floor roughness of the wafers decreased with the rise within the time of utilizing the noticed wire. It additionally exhibits that the curvature of the noticed marks on the wafer floor will increase with the rise of the noticed wire utilization time.

Additionally, the crew discovered that the distribution of the fracture likelihood density curve was extra targeting the entrance wafers, whereas it was extra dispersed on the again wafers. It additionally determines that the fracture traits of the center wafers and the again wafers are the identical.

They additionally discovered that the attribute fracture energy of bending within the course perpendicular to the noticed marks is 2 or thrice that of bending within the parallel course of the noticed marks.

“The relationship between the noticed wire utilization time, the floor roughness, and the traits of the noticed mark with the breaking energy of the silicon wafer is revealed, which supplies a course for improvement for bettering the energy of the large-scale that ultra-thin silicon wafers and diminished fracture risk within the manufacturing course of,” mentioned the teachers.

This content material is protected by copyright and is probably not reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

Popular content material

[ad_2]

Source link