[ad_1]

The Fraunhofer Institute for Microstructure of Materials and Systems (Fraunhofer IMWS) has developed a technique to enhance lifetime predictions of inverters, to assist producers cut back materials use and testing efforts whereas decreasing manufacturing prices. with out compromising the lifetime of the gadget.

From pv journal Germany

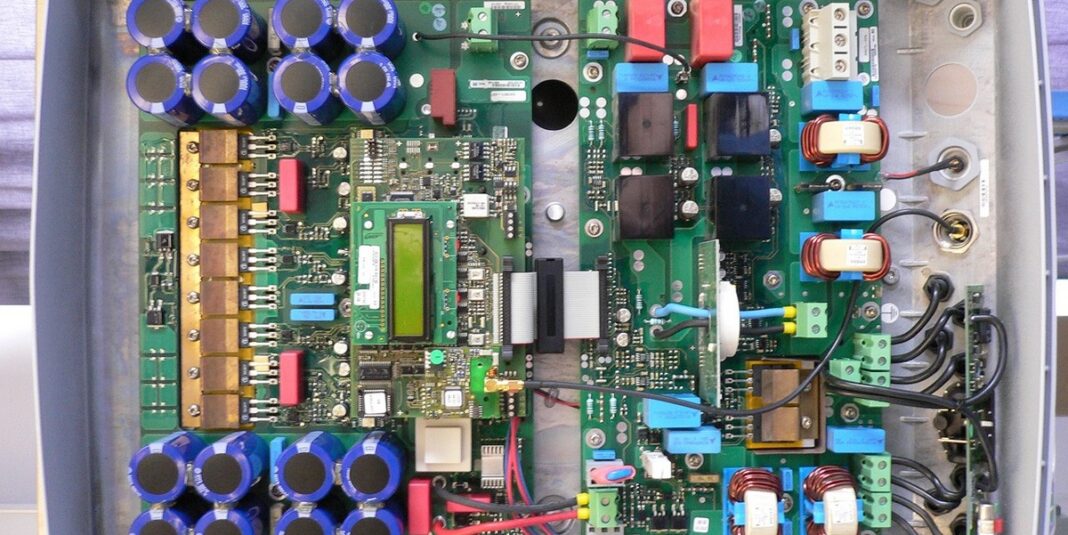

Inverters for PV programs, battery storage, and electromobility should face up to harsh environmental components resembling climate, filth, excessive voltage, and lengthy working hours.

Despite these challenges, high-quality inverters usually final 20 to 25 years. However, the particular development strategies, supplies, and designs that guarantee this longevity stay unclear, particularly in new functions resembling PV and electromobility.

To handle this, inverters are sometimes over-engineered with security margins, utilizing supplies and processes that supply sturdiness with no detailed understanding of growing older and failure mechanisms. This ends in larger prices.

In response, Fraunhofer IMWS, the University of Stuttgart’s Institute for Machine Elements, and the German corporations SMA, Electronicon Kondensatoren, and Merz Schaltgeräte have developed a technique to enhance service life and reliability predictions for inverters. and their key parts.

“Our outcomes allow correct design growth of latest inverters and quicker high quality management exams,” mentioned Sandy Klengel, a undertaking supervisor at Fraunhofer IMWS. “This permits the discount of producing prices, as a result of now we have a deeper understanding of the habits of the parts.”

Fraunhofer IMWS research faults and growing older processes in movie capacitors and electromechanical switching gadgets, resembling DC circuit breakers and relay assemblies.

Researchers create defects and set off degradation mechanisms in lab circumstances utilizing specifically developed check setups. They bear in mind materials interactions, numerous electrical masses, and environmental influences resembling seasonal temperature modifications, humidity, and corrosive brokers resembling salt spray.

They then test which wonders are appropriate for real-world use by evaluating lab outcomes with field-aged parts that stay intact.

The findings revealed points resembling cracks in ceramic layers affecting insulation, oxide layer formation, demetallization, polymer degradation, thermal degradation, and solder degradation. The researchers additionally famous crystalline deposits, native melting, contamination, and failure of housing parts.

The crew compiled these findings right into a catalog summarizing failure varieties, traits, and causes. They additionally used numerical simulations to raised perceive the physics of failure, resembling native present density and warmth loss in switches.

“With the outcomes, producers can now cut back materials necessities and testing effort and thus cut back gadget prices – with out compromising the reliability and repair lifetime of the inverters,” Klengel mentioned. .

This content material is protected by copyright and might not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

Popular content material

[ad_2]

Source link