[ad_1]

Italian researchers have developed a dual-source warmth pump system that makes use of a finned-coil evaporator and a photo voltaic evaporator made with three photovoltaic-thermal panels. Thanks to the mixed motion of the 2 evaporators, the warmth pump can obtain the next evaporation stress and coefficient of efficiency.

Researchers on the University of Padua in Italy have designed a dual-source warmth pump that makes use of CO2 as a refrigerant and a photo voltaic evaporator consisting of three PV-T collectors.

“The key innovation lies within the mixed operation of the 2 evaporators, the finned-coil and the PV-T collectors, which permits the selection between wind and photo voltaic vitality or their simultaneous use,” the scientists mentioned. “The new resolution offered right here doesn’t have to divide the refrigerant circulation price between the 2 evaporators and on the identical time it solves the issue of doable distribution contained in the evaporators. “

The proposed 5 kW CO2 solar-assisted dual-source warmth pump (CO2 The SA-DSHP) system can work with two forms of evaporators concurrently or solely certainly one of them, with the PVT collector capable of act as an evaporator, as a result of the refrigerant flows immediately by way of the PV-T tubes.

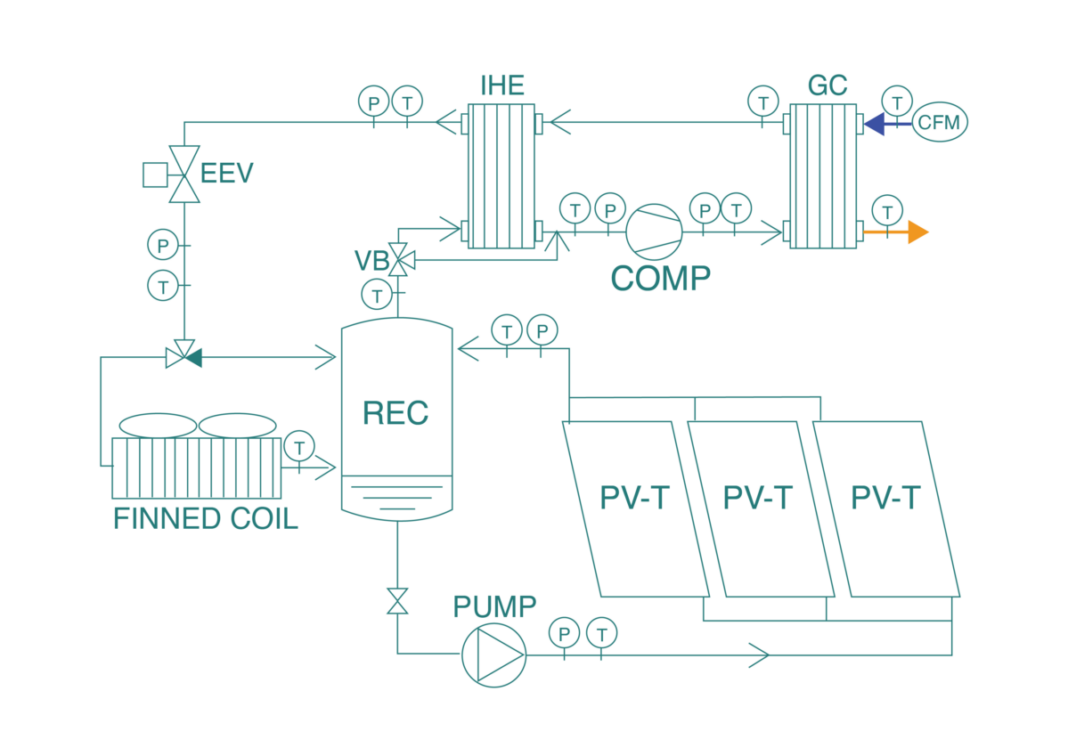

It consists of an inverter-driven airtight vertical rotary compressor (COMP), an inside warmth exchanger (IHE), a gas-cooler (GC), a finned coil warmth exchanger used as an air evaporator, and the photo voltaic evaporator consisting of three. PV-T collectors. The 270 W PV panels are put in in a plate-and-tube warmth exchanger that permits the evaporation of the refrigerant circulation and the cooling of the photovoltaic cells, which in flip improves their efficiency. It additionally features a throttling valve, a circulation pump, and a cylindrical tank that acts as a receiver.

The system can work in three modes: air-mode (AIR-M); solar-mode (SOL-M); and simultaneous-mode (SIM-M). When working beneath AIR-M, the warmth pump makes use of solely air as a low-temperature thermal supply, whereas in SOL-M it makes use of solely photo voltaic irradiance as a thermal supply. Under SIM-M mode, it makes use of photo voltaic irradiance and wind.

“In all modes of operation, between the low-pressure receiver (REC) and the compressor suction line, the CO2 flows by way of the IHE, which is used to warmth the refrigerant earlier than it enters the compressor,” the workforce defined. “To modify the extent of superheating, a three-way valve (VB) is used to bypass part of the full refrigerant circulation price coming from the REC.”

Through a collection of checks carried out in winter environmental situations, the teachers analyzed the coefficient of efficiency (COP) and energy consumption of the system. They set a compressor and fan pace of fifty%, a pump pace of 40%, a excessive stress of 80 bar, and water heated from 30 C to 35 C.

“An experimental comparability between three totally different modes of operation of the warmth pump was carried out in the identical ambient situations and operative situations,” they mentioned, noting that the PV panels had been operated to attain ot the utmost energy manufacturing.

The evaluation reveals that the warmth pump working in SIM-M can obtain larger stress evaporation and better COP in comparison with these working in AIR-M and SOL-M. “Simulation outcomes present that simultaneous-mode operation may be outperformed by solar-mode solely at excessive irradiance and low air temperature, when the evaporation temperature is larger than the air temperature,” added the scientist.

Their findings are within the examine”The benefit of operating a direct growth CO2 warmth pump with solar-and-air simultaneous warmth sources: experimental and numerical investigation,” revealed in Applied Energy.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].

Popular content material

[ad_2]

Source link