[ad_1]

The Chinese module maker and the Australian National University used phosphorus diffusion gettering and one other defect mitigation technique to enhance the standard of n-type wafers. The proposed course of contributes to the advance of the fabric high quality particularly within the tail ends.

Researchers from the Australian National University and Chinese PV module producer Longi investigated the wafer high quality of n-type industrial ingots produced by the Recharged Czochralski (RCz) course of, making use of two methods in defect discount – Tabula Rasa (TR) and phosphorus diffusion gettering (PDG) – to additional enhance most lives.

TR is normally used to dissolve any oxygen clusters or precipitates in Cz ingots, whereas PDG includes three steps and is used throughout crystal development to take away inclusions and different types of defects on wafers. Through gettering, impurities are first launched right into a strong resolution after which bear diffusion by means of the silicon. Finally, they’re trapped in an space away from the energetic circuit areas of the wafer.

“The most stunning discovering is the extent to which melting recharging can persistently produce very high-quality materials, which has constructive implications for enhancing photo voltaic cell efficiencies,” stated by corresponding creator Afsaneh Kashizadeh. pv journal. “The most difficult side of the research was the correct measurement of Auger-limited lifetimes utilizing the lab’s analysis gear. This required meticulous calibration and repeated validation of our floor passivations movies and measurement strategies.

The implementation of each methods is adopted by a high-temperature boron diffusion step, which the analysis staff says is consultant of the very best thermal finances step within the tunnel oxide passivated contact (TOPCon) cell fabrication course of.

The Recharged Czochralski (RCz) crystal development course of, which allows crucible re-use with out energy between pulls, is more and more used to provide ingots for n-type and p-type wafers on account of its productiveness and price discount advantages.

To assess the standard of RCz n-type wafers, the researchers first characterised the as-grown materials earlier than subjecting the fabric to high-temperature testing processes. Samples are measured straight on ingots and passive wafers.

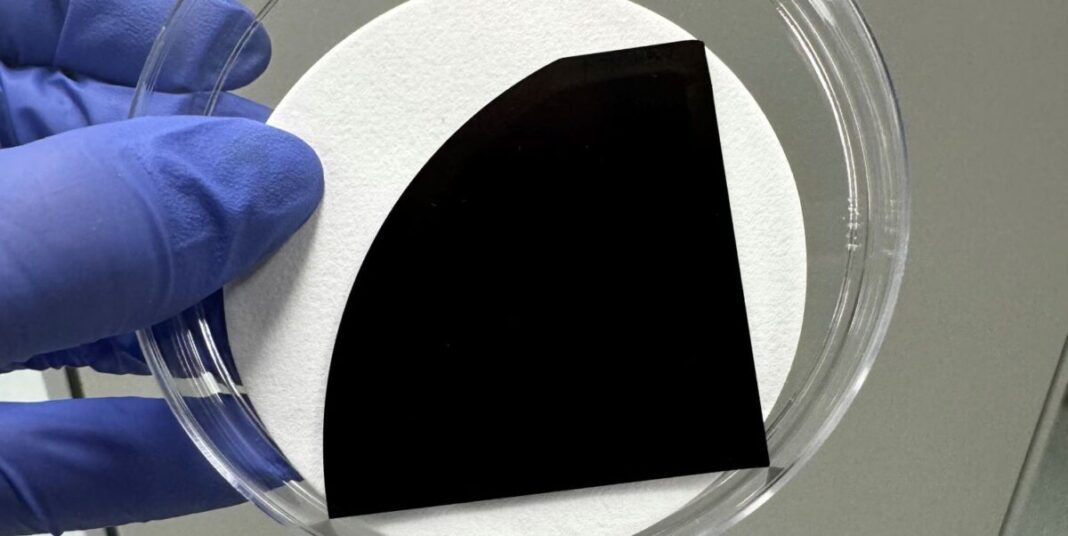

The staff grew seven ingots with a crucible after which chosen three ingots to provide wafers lower from 16 completely different positions from every of the three ingots, marking it with completely different solidified fractions. The wafers equipped by Longi are laser lower from the middle of pseudo-square M10-sized n-type RCz silicon wafers.

There are three teams of specimens, one that continues to be untreated, a second group that undergoes TR remedy in a standard quartz tube furnace for half-hour in an oxygen setting, and the third group is PDG handled.

“Our research reveals that industrial n-type wafers grown by RCz are near the Auger restrict underneath open-circuit circumstances within the as-cut state, and that after PDG they successfully attain this restrict ,” the staff said. “Our outcomes present that the utmost voltage on the energy level is outlined enhanced by 5-15 mVparticularly close to the tail-end, suggesting that these wafers would profit from the extraction course of offered by the usual TOPCon processes, though it might be completely different from these used on this research, or from a pre-gettering step for heterojunction cells.

The researchers additionally famous that the wafers “may gain advantage from the extraction course of offered by the usual TOPCon processes, though it might be completely different from these used on this research, or from a previous extraction step for in heterojunction cells.”

They additionally discovered that, after boron sputtering, the majority lifetimes of the samples didn’t lower considerably, suggesting that these wafers are steady at excessive thermal budgets. “We additionally conclude that the standard of successively grown ingots doesn’t lower considerably, even after many ingots are faraway from the recharged soften, and the entire ingots may be appropriate for high-efficiency photo voltaic cells with none want for added processes at excessive temperatures,” they stated

Details of the experiment, together with wafering, etching and cleansing steps, checks, and outcomes are described in “Auger-limited Bulk Lifetimes of Industrial Czochralski-Grown n-Type Silicon Ingots with Melt Recharging,” revealed in Solar Energy Materials and Solar Cells.

According to Kashizadeh, the curiosity of friends within the research is centered on the distinctive “means to manage the focus of oxygen at low ranges and obtain lengthy life all through the method with out counting on strategies akin to magnetic confinement of the soften.

Looking forward, he famous plans to research the standard of next-generation n-type silicon wafers doped with antimony. “Preliminary outcomes present that these wafers have larger mechanical power in comparison with phosphorus-doped ones. In addition, we see extra uniform resistance all through the ingot development course of, stated Kashizadeh.

This content material is protected by copyright and is probably not reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

Popular content material

[ad_2]

Source link