[ad_1]

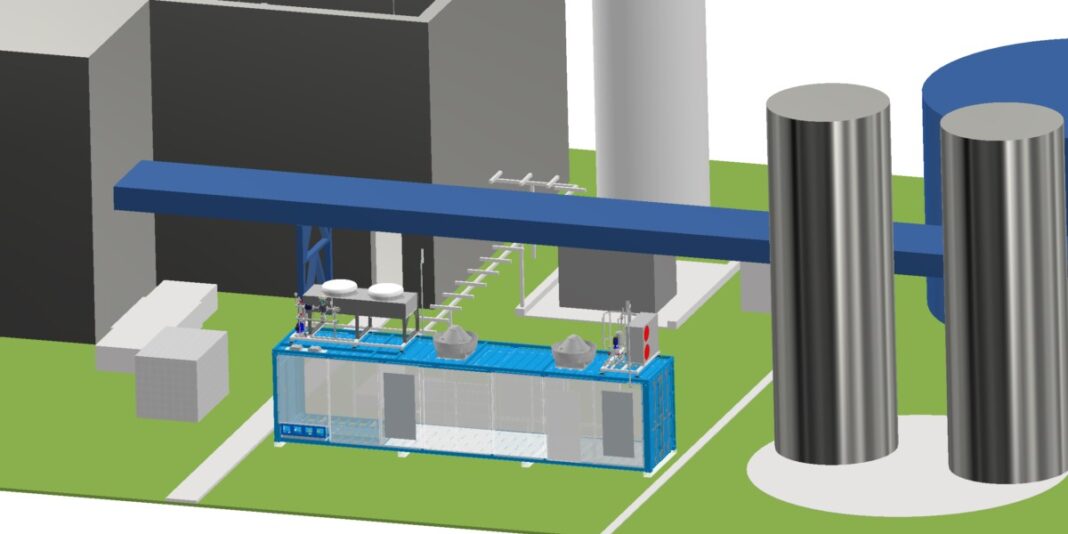

The crew from Fraunhofer IEG developed their progressive LA-SeVe electrolysis plant from sketch to actuality.

Source: Fraunhofer IEG/Tobias Sauerstein

From pv journal Germany

The Fraunhofer Institute for Energy Infrastructures and Geothermal Systems (IEG) has established a brand new Laboratory Facility for the Sector-Coupled Utilization of PEM Electrolysis Products (LA-SeVe) in Zittau, Germany. The metropolis has now granted the constructing allow, the analysis institute introduced on Wednesday.

The check facility might be constructed on the positioning of Zittau ppublic utilities early subsequent yr for round €2.7 million. It contains an electrolyzer, which might be situated in an indoor chamber about 12 meters lengthy and a couple of.5 meters vast and equipped with electrical energy by way of a brand new transformer station. In addition, a warmth pump with a most output of 105 kW (thermal) might be put in in an present corridor along with buffer storage, pumps and management expertise and related to the electrolyzer by way of a water circuit. The waste warmth from the electrolyzer analysis operation might be directed by way of the warmth pump to the town’s district heating community.

The check facility is a part of the IntegrH2ate venture, the place the connection between PEM electrolysis, warmth pump and heating community is investigated. The waste warmth from electrolysis might be upgraded to a warmth pump in order that it may be used as district heating within the metropolis’s provide community. Oxygen from electrolysis can be a wanted product whether it is pure sufficient, the researchers defined. The check facility is primarily used to check the operational optimization of the system idea and the environment friendly coupling of electrolyzers and warmth pumps to electrical, warmth or hydrogen-driven operation. The working mode and parameters are modified relying on whether or not the main focus is on utilizing extra electrical energy from renewable vitality crops, saving fossil fuels or optimum hydrogen manufacturing. Fraunhofer IEG researchers have already developed ideas for these situations and now they are often examined in observe.

“With our check services, we create a check infrastructure to check and qualify industrial processes,” says Clemens Schneider, venture supervisor at Fraunhofer IEG. “We need to check on a pilot plant scale how the warmth and oxygen merchandise from electrolysis may be effectively processed in dynamic operation.”

The check facility can be meant as a platform to check industrial processes for producers and firms. It contains the methanation of carbon dioxide, closed carbon cycles, exams of compressors for oxygen and hydrogen in addition to hydrogen burners and different elements to make use of the principle and merchandise from the electrolysis of PEM.

PEM stands for proton alternate membranes or polymer electrolyte membranes. PEM electrolyzers have good partial load capability and excessive effectivity. They are additionally thought-about insensitive to load modifications. They are subsequently nicely fitted to the manufacturing of inexperienced hydrogen from renewable sources corresponding to photovoltaics and wind energy.

This content material is protected by copyright and might not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

Popular content material

[ad_2]

Source link