[ad_1]

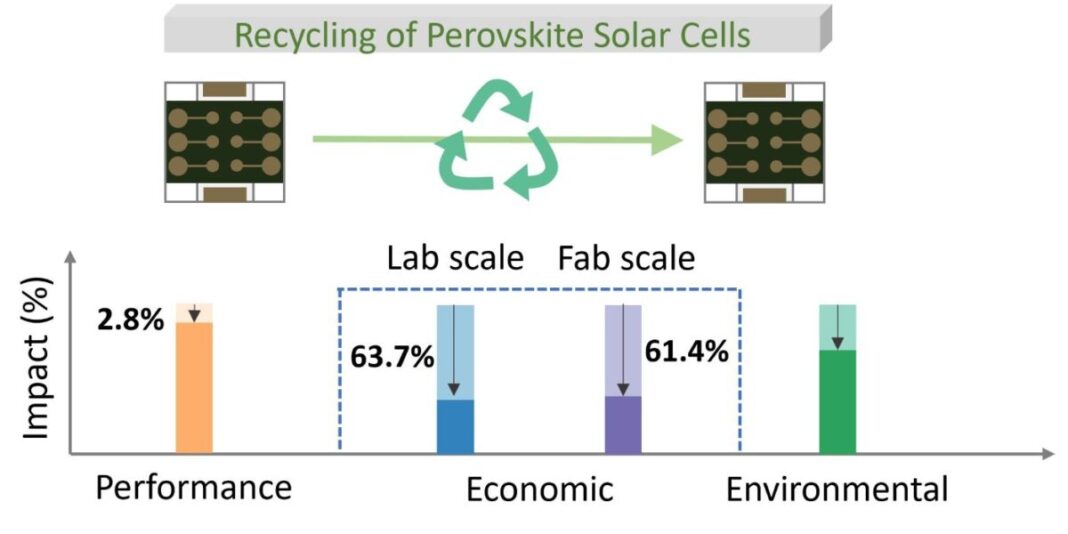

A German analysis workforce has developed a brand new approach to recuperate and reuse methylammonium lead iodide (MAPbI3) from perovskite photo voltaic cells by solvent extraction. Such a recycling methodology can save as much as 61% of lab and industrial manufacturing prices.

A German analysis workforce on the Helmholtz Institute Erlangen-Nürnberg for Renewable Energy, Jülich Institute for Energy, reported the success of recovering every layer of a planar. methylammonium lead iodide (MAPbI3) perovskite photo voltaic cell utilizing a layer-by-layer solvent extraction method, adopted by purification to revive high quality.

“This methodology can enable as much as 99.97% recycled mass, thus saving sources and decreasing waste,” say the scientists “Technology projections recommend that the proposed methodology of recycle has the potential to generate vital value financial savings.In the lab, recycling can scale back materials prices by as much as 63.7%, in industrial manufacturing by as much as 61.4%.

“It stunned me that it’s attainable to recuperate such a excessive proportion of the unique materials, and that there’s a clear financial profit in recycling even on a lab scale,” the corresponding writer of the analysis , Ian Marius Peters, mentioned. pv journal.

The researchers defined that the halide perovskite photo voltaic cell supplies could be obtained and processed to a high quality that it may be used to create a brand new photo voltaic cell with out vital lack of materials high quality and gadget effectivity. “The layers of solution-processed photo voltaic cells could be separated comparatively simply by selective melting,” they emphasize.

The challenge seems easy, however it’s not. Recycling the spiro-OMeTAD materials used within the maintain transport layer (hTL) will not be straightforward because of the presence of residues and plenty of components, in accordance with Zhenni Wu, the lead researcher of the examine. “Ultimately we discovered that reusing spiro-OMeTAD, whereas sustaining cell effectivity, doesn’t require full removing of impurities,” Wu mentioned. pv journal.

“We began the method within the lab. The constraint is that we’ve got to start out from nearly zero. We are nonetheless engaged on our setup. Next, we need to enhance the effectivity, and we need to present that you may additionally do it for a module ,” mentioned Peters.

To assess the standard of the recycled materials, the workforce made quite a lot of photo voltaic cells, some with a number of layers of recycled materials, and others made fully of recycled supplies. “Each mixture offers an effectivity corresponding to cells made solely of recent supplies, demonstrating the effectivity of the developed recycling course of,” mentioned the workforce.

Two sorts of gadgets are assembled: one is a typical small space practical cell made by spin coating; the opposite is a bigger pseudo-module ready by physician blading or drop-casting. The stack is as follows: indium tin oxide (ITO), a tin(IV) oxide (SnO2) layer, a MAPbI3 perovskite absorber, a spiro-OMeTAD gap transport layer, and a gold (Au) contact.

The researchers famous that the stack was chosen for a number of causes, one in all which is that it permits the selective removing of supplies.

In a dialogue of the worth and weight of the fabric, the workforce emphasised that ITO glass has the “highest recycling precedence” as a result of it accounts for greater than half of the worth and makes up a lot of the mass of module, which is 99.9% . “Being capable of reuse the substrate impacts the financial viability in addition to the sustainability steadiness of the cell,” it mentioned, including that the transition to FTO must be thought of.

Popular content material

It additionally highlights that the high-cost spiro-OMeTAD requires a extra environment friendly and scalable preparation methodology. Until replacements are discovered, recycling the fabric is “important.” Another essential facet is the usage of lead. The workforce says its presence in metallic halide perovskite photo voltaic cells might require establishing restoration processes as a prerequisite for commercialization.

As the analysis findings present, the adoption of recycling and environmentally pleasant expertise has implications for design and manufacturing. For instance, the solvents used within the manufacturing of perovskite photo voltaic cells.

Wu defined that a lot of the solvents used in the present day are harmful. “Future analysis ought to give attention to discovering greener alternate options to scale back carbon footprints. Similarly, environmentally pleasant solvents must be prioritized for recycling processes,” mentioned Wu.

“The takeaway is that you should recycle the elements of perovskite photo voltaic cells, particularly the substrates. This is true not just for business but additionally for labs,” mentioned Peters.

Details of the examine could be discovered within the paper “Closing the loop: recycling MAPbI3 perovskite photo voltaic cells,” printed in Energy & Environmental Science.

This content material is protected by copyright and might not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link