[ad_1]

The National Renewable Energy Laboratory has famous a rise in glass breakage in photo voltaic panels. The PV Module Index from the Renewable Energy Test Center examines these and different glass-related developments in photo voltaic manufacturing.

From pv journal USA

Glass is a singular materials used for its chemical stability and visible transparency. It is normally utilized in photo voltaic panels as a protecting outer layer.

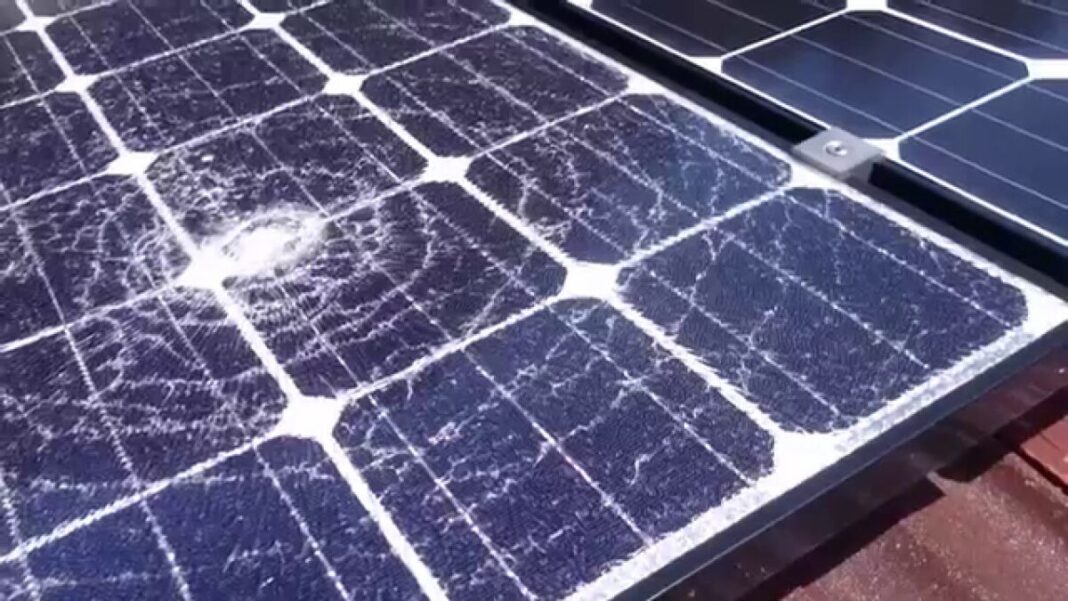

In this yr PV Module Index, the Renewable Energy Test Center (RETC) examines rising points in photo voltaic glass manufacturing and subject efficiency. It discovered reviews of rising photo voltaic panel glass breaking violently within the subject, typically even earlier than commissioning.

Teresa Barnes, Ph.D., directs the Photovoltaic Reliability and System Performance Group on the National Renewable Energy Laboratory (NREL). Barnes and his colleagues at NREL reported the difficulty.

“The speedy breakage of the glass is an instance of a failure mode that we’re not used to seeing. When I first began engaged on photo voltaic module reliability seven or eight years in the past, we regularly heard concerning the breakage of glasses when there are sloppy operations and upkeep procedures,” Barnes mentioned.

Today, that is not the case, and the NREL reliability workforce frequently receives reviews of glass breakage in silicon modules unrelated to direct harm from upkeep or storm results. The workforce discovered that over time, the common high quality of photo voltaic glass seems to be declining.

“It was once the case that the modules would move the IEC 61215 static load check with a big security issue,” says Barnes. “Today, modules barely move the bottom static load check or they do not move with increased security elements. Some new module designs simply do not move the minimal static load check.”

The NREL workforce has begun to hypothesize that cup harm in photo voltaic panels goes by means of an identical course of to a automotive windshield that wants alternative. When a windshield is broken on affect, it normally solely exhibits up as a small star-shaped mark that appears insignificant. But when extreme climate circumstances with very excessive or low temperatures move, the severity of the harm is absolutely realized, and immediately a big crack seems on the whole floor.

“We suppose that the identical dynamic could also be accountable for the speedy breakdown of photo voltaic glass,” Barnes mentioned.

This improve in breakage is probably going because of the pattern of photo voltaic glass shrinking over time, NREL mentioned. Mike Pilliod from Central Tension, talking at NREL’s 2024 PV Module Reliability Workshop mentioned that any producer can mood the glass to three mm. But under 3 mm, glass tempering is a troublesome course of. He mentioned that as glass will get thinner, smaller defects are wanted to create defects that restrict the glass’s energy. These flaws are being actively studied at NREL to know a few of the potential pitfalls of utilizing skinny glass in photo voltaic manufacturing.

Barnes cautioned that it could be a mix of results that makes glass breakage a better menace than earlier than. Modules are getting larger, frames are getting thinner, and mounting rails are getting nearer. All of those elements result in “massive, floppy modules” that put extra strain on the glass floor, which additionally thins out extra modules.

The NREL workforce mentioned at this yr’s PV Module Reliability Workshop, producers are beginning to speak about introducing thicker frames and wider mounting positions.

“As individuals higher perceive how the module system interacts, they’ll work to optimize how the masses are balanced,” Barnes mentioned. “The pendulum in that balancing act might now be swinging forwards and backwards on the integrity of the body and the mounting rail.”

While different module suppliers give attention to frames and mounting, others introduce tempered glass modules which is marketed as ice-hardened and sturdy in extreme climate.

The RETC requested Barnes about current catastrophic losses in Texas, the place hailstorms precipitated lots of of tens of millions of {dollars} in harm to operational photo voltaic belongings.

GCube Insurance, an underwriter for renewable power, mentioned that regardless of just one.4% of the overall variety of insurance coverage claims being filed, about 54% of complete photo voltaic loss prices may be attributed to rain. ice. This relies on information collected by Gcube over the previous 5 years. The common price amounted to $58 million per declare.

“Ten years in the past, individuals would not be in a railroad assembly in case you talked about climate-specific module designs. The consensus was that it could be too costly,” Barnes mentioned. climate-specific module and climate-specific testing are beginning to look possible as we see extra emphasis on complete system price. It’s potential we’ll see ice-hardened modules, particularly in a market just like the United States, the place it is perhaps value paying extra for hail energy.

This content material is protected by copyright and is probably not reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link