[ad_1]

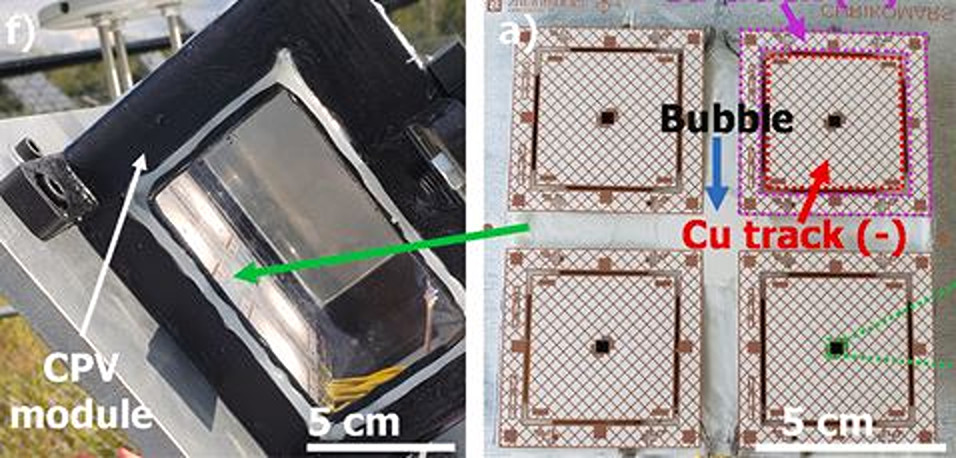

A Canadian analysis group has optimized the efficiency of concentrator photovoltaics through the use of so-called surface-mount expertise for thermal administration. The CPV module prototype makes use of 4 unconnected III-V germanium cells, a Fresnel lens, and a clear glass printed-circuit board.

Scientists from Canada’s Université de Sherbrooke have developed a prototype of a concentrator photovoltaic (CPV) module based mostly on so-called surface-mount expertise (SMT) – a method generally used to mount digital elements on surfaces in a print. circuit board (PCB).

The proposed SMT design doesn’t use wire bonding for the cell emitter connection and is meant to extend the warmth dissipation of the CPV panel, which in flip can scale back its working temperature and enhance its efficiency.

“SMT, which makes use of a conductive solder paste for interconnection, has the benefit of being inexpensive and quicker for large-scale manufacturing, and SMT tools requires much less house than wire-based wiring tools, ” they defined. “We developed and used the SMT course of, which mixes meeting flexibility and improved alignment of photo voltaic cells, to assemble photo voltaic cells bigger than one millimeter in dimension. “

The 4-solar cell CPV module prototype makes use of a Fresnel lens to pay attention mild onto cells soldered to a clear glass PCB and guarded by lamination layers. The emitter contacts are soldered through conductive solder joints to a glass PCB, which embeds steel tracks for non-soldered areas. The clear underfill fills the hole between the photo voltaic cell and the PCB to stop reflections on the interfaces on the underside plate of the module.

“The underfill fillets defend the perimeters of the photo voltaic cell to stop brief circuits and contribute to the thermomechanical stability of the meeting,” the analysis crew said. “The again floor of the meeting is laminated with an EVA encapsulant and a Tedlar protecting sheet to protect the photo voltaic cells from the setting.”

Image: Université de Sherbrooke, Solar Energy Materials and Solar Cells, Common License CC BY 4.0

The 4 cells used within the system aren’t related to one another, and are triple-junction III-V germanium photo voltaic cells, every with an energetic floor space of 8.751 mm.2. The value of photo voltaic cells based mostly on compounds of III-V materials parts, named in keeping with the teams of the periodic desk to which they belong, restricts units to area of interest purposes, reminiscent of drones and satellites. These are purposes the place low weight and excessive effectivity are extra vital considerations than prices.

The scientists mounted the 4-cell CPV SMT module on a 2-axis photo voltaic tracker from the Helios platform on the University of Sherbrooke.

The crew took a collection {of electrical} and temperature measurements of the system beneath actual working circumstances and in addition performed a collection of simulations based mostly on the finite component mannequin (FEM), specifically a numerical approach used to carry out finite component evaluation (FEA) of bodily phenomenon.

Through their evaluation and experiments, the lecturers discovered that the size of the steel ribbon on the again of every cell and the steel protection ratio of the PCB are the important thing elements within the thermal administration of the CPV module, whereas the opposite substances have much less impact. of module temperature.

“The temperature of the photo voltaic cell might be saved beneath 80 C by a variety of steel ribbon behind the photo voltaic cell, each for a steel protection of the PCB of 0% or 100%,” they added. defined. “However, this dimension dimension is way wider when the steel protection ratio is 100% than when the PCB steel protection ratio is 0%. The simulation additionally exhibits that the temperature of the photo voltaic cell can attain 54 C with copper ribbon and 57 C with aluminum ribbon.

The system is described within the paper as “Finite component modeling and experimental validation of concentrator photovoltaic module based mostly on floor mount expertise,” revealed in Solar Energy Materials and Solar Cells. “These outcomes present that along with simplifying the meeting course of, the usage of SMT for CPV modules fabrication improves the warmth dissipation of the metallic layer of the glass PCB and the again facet contact,” the researchers concluded. “This opens the door to less complicated CPV modules, larger efficiency CPV modules and better focus ratios.”

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link