[ad_1]

Researchers in Niger have proposed using photovoltaic vitality to energy the operations of evaporative cooling greenhouses. The proposed experimental answer makes use of regionally manufactured pads and is reported to have the ability to compete with industrial counterparts.

A bunch of researchers from Abdou Moumouni University in Niger has proposed using photovoltaic vitality for powering evaporative cooling greenhouses (ECGs) within the Sahel area of Africa.

ECGs are a kind of greenhouses that cool crops utilizing a pure strategy of evaporation. The evaporation course of is finished by pumping water into particular moist pads whereas followers push air by them.

“Under Sahelian dry and sizzling climate circumstances, cooling is important to keep up a very good microclimate,” defined the analysis group. “To keep away from the standard costly and unsustainable cooling system within the Sahel with air conditioners related to the grid or by turbines powered by carbonated fossil fuels, a standalone photovoltaic system is used to energy the evaporative cooling system, which is water pumping and distribution and ventilators.

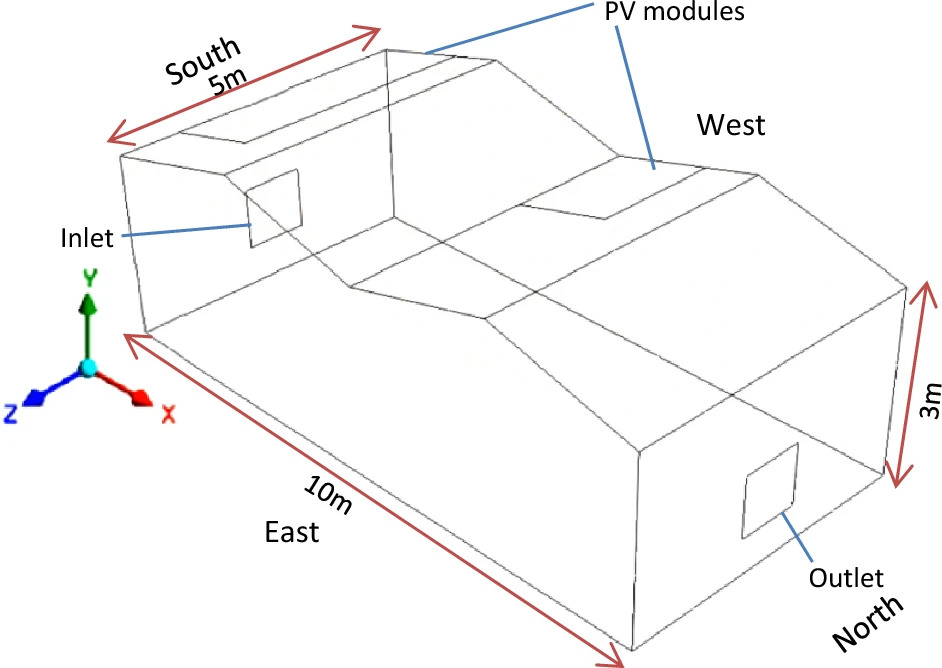

The experimental set-up is situated within the southwest of Niger and covers an space of 50 m2, with a top of three.66 m and a roof slope of 15 levels. The water pumping and ventilator are powered by six PV modules with an output of 260 W every, utilizing an inverter of 5 kVA. Four batteries of 150 Ah every are additionally used to make sure easy operation in case of lack of irradiation.

As for moist pads, lecturers in contrast two several types of the identical system. One is the industrial Celdek pads (C-pads), whereas the opposite is regionally manufactured Hyphaene thebaica fiber pads (HF-pads). In each instances, the pads are inserted alongside the edges of the greenhouse, with one fan per pad.

“Field local weather parameters recorded in situ and thermophysical information obtained on the laboratory prototype stage and from the put in PV-ECG have been used to judge the choice cooling potential of the HF-pad in opposition to standard C-pad,” the lecturers defined. “Greenhouse key cooling performances derived from established vitality and mass stability thermodynamic equations.”

In addition, after amassing information from an actual greenhouse and conducting a lab investigation of the pads, a computational fluid dynamic (CFD) evaluation was carried out to realize a basic understanding of the refrigerant fluid distribution. within the greenhouse. The numerical mannequin and the experimental information assortment have been carried out in sizzling and dry seasons, with an enter temperature of 35 C to 45 C and a relative humidity of 10% to fifteen%.

“The cooler utilizing the HF-pad permits sustaining the microclimate under 25 C, with a most humidity fee of as much as 80%, beneath harsh ambient circumstances,” the group emphasised. “HF-pad has the best cooling coefficient of efficiency (COP = 9 in opposition to 6 for C-pad), the most effective cost-to-efficiency ratio (CER = 5; 4 occasions decrease than C-pad) , and the bottom outlet temperature (20.0 C).”

The scientists additionally emphasised that because of the larger air velocity on the outlet, the C-pad cooler spreads chilly air as much as 1.25 m farther than its counterpart, creating a better atmospheric strain, which has twice the turbulent kinetic vitality.

The group concluded that the HF-pad achieves cooling performances that compete with standard pads. “Optimizing the HF-pad body engineering and the know-how scaling as much as the commercial stage can permit higher thermal and financial performances,” they added.

Their findings are introduced in “Improving the sustainability and effectivity of photovoltaic evaporative cooling greenhouses within the Sahel,” revealed in Scientific reviews.

This content material is protected by copyright and will not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link