[ad_1]

A Chinese-Canadian analysis workforce has proposed a brand new PV mounting answer that depends on two varieties of spacers and two varieties of clamps that may be printed utilizing widespread printing supplies. The price of the completely different options introduced varies from CAD1.50 ($1.10) to CAD3.83.

A bunch of researchers from the University of Western Ontario in Canada has developed and examined 3D-printed mounting mechanisms for wood racking of PV modules. Open-source designs, other than enabling distributed manufacturing, are additionally claimed to be cheaper and have decrease embodied vitality and embodied carbon in comparison with standard racking supplies.

“Wood-based racks are significantly appropriate for ground-mounted agrivoltaics however can be utilized anyplace,” mentioned corresponding creator Uzair Jamil. pv journal.

According to the analysis workforce, wood racks additionally supply benefits comparable to ease of distribution in manufacturing, a decrease price per W of supplies, and no corrosion or rusting. “The drawback with wood-based racking is that they can not do the usual front-face attachments that at the moment are widespread in proprietary aluminum racking techniques. For the primary time, this paper introduces novel 3D printed clamps for front-surface photo voltaic module mounted on wooden racking constructions,” they mentioned.

The researchers proposed 4 varieties of mounting mechanisms, which had been simulated utilizing Abaqus software program and finite aspect evaluation (FEA), which are sometimes used to unravel differential equations that come up in engineering and mathematical modelling. Each mechanism was simulated printed utilizing one in every of three widespread printing supplies: polyethylene terephthalate glycol (PETG), acrylonitrile styrene acrylate (ASA), and polycarbonate (PC).

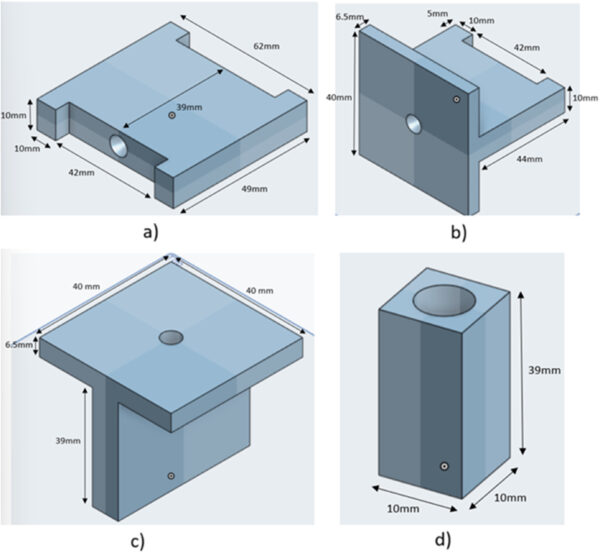

In all circumstances, the mounting mechanism is meant to help 410 W modules with dimensions of 1,880 mm x 1,042 mm x 40mm and a mass of 19.7 kg. It can also be designed to make use of 127 mm lengthy lag bolts with a diameter of 6.4 mm. A 7 mm huge gap is designed in all 3D-printed components to accommodate the bolt.

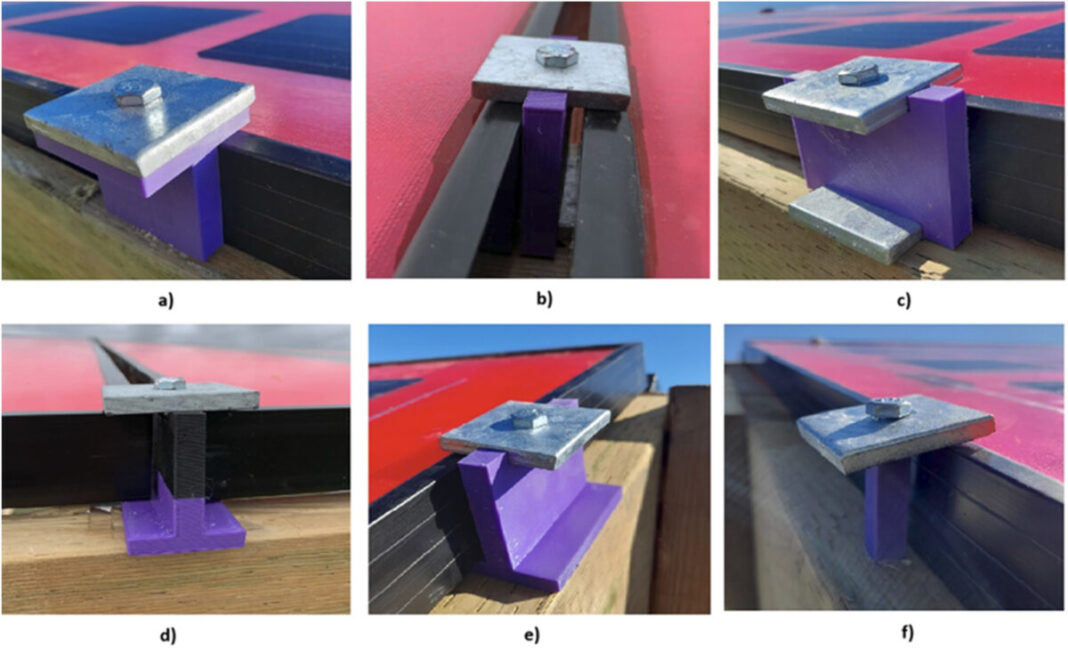

The first mechanism is the T-shaped clamp, the place the T-bar is positioned on the body of the PV module and holds the module within the racking construction. In this case, a flat washer is positioned between the bolt and the 3D-printed elements to stop harm to the clamp. Another proposal makes use of a U-shaped clamp, which makes use of its personal base to relaxation the module whereas the sq. washer holds the module from above.

Image: SUniversity of Western Ontario, Renewable Energy, Creative Commons License CC BY 4.0

The subsequent two mechanisms are spacers. At first, a sq. spacer is used with a sq. washer to help the motion of the modules. In the second, an H-shaped spacer is supported by two sq. washers that maintain the photo voltaic modules, whereas the mount serves as a spacer between them.

“Of all of the designs, the T-shaped clamp configuration confirmed higher outcomes with the best stress within the aluminum (Al) body of 34.27 MPa,” mentioned the researchers. “The highest stress was noticed within the U-shaped spacer for the spacer (4.53 MPa – PC materials), bolt (32.01 MPa – PETG materials) and body (37.30 MPa) and for the washer within the H-spacer (42.77 MPa). The mises weights for all designs, nevertheless, will likely be discovered inside the allowable limits qualifying the clamping method for use for future installations.

After the simulation outcomes, the teachers printed a number of mounting mechanisms to make sure their applicability within the discipline. “All 4 clamps are straightforward to put in,” they emphasize. “No set up points had been noticed whereas tightening the lag screw. Using a predrill earlier than tightening the lag screw, nevertheless, made the tightening/screwing operation simpler.”

In addition, the group carried out an financial evaluation of manufacturing, accounting for the costs of supplies used for printed components, energy consumption, printing time, electrical energy charges, washer prices, and prices on the bolts.

“The price of the completely different options introduced varies from CAD1.50 ($1.10) to CAD3.83 for the sq. spacer and U-shaped clamp, respectively,” they mentioned. “The out there options available on the market are largely all metallic clamps and typically much more costly, from CAD 1.76/piece to CAD4.50/piece. This is a 14.7% to 66% price financial savings for mounting clamps.”

The proposed mechanisms are introduced in “Distributed Manufacturing for Distributed Generation: 3-D Printed Solar Photovoltaic Module Mounting Mechanisms for Wood Racking,” revealed in Renewable Energy.

“Our Free Appropriate Sustainability Technology (FAST) Research Group is at the moment engaged on totally 3D printed PV modules. We are additionally wanting on the alternative to create 3D-printed frames for frameless PVs,” Jamil mentioned. .

This content material is protected by copyright and might not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link