[ad_1]

Sign up for day by day information updates from CleanTechnica by e-mail. Or comply with us on Google News!

Perovskite photo voltaic cells have been talked about because the early 2000s as the following massive factor in renewable power, driving down prices whereas growing manufacturing volumes. There isn’t any such factor as a free lunch, getting the perovskite materials to behave is a troublesome endeavor. However, the hole between the laboratory bench and real-world functions is closing, as proven by the latest exercise of researchers and producers.

Raising the Bar On Perovskite Solar Cell Efficiency

Perovskite is a category of artificial crystalline supplies with wonderful optoelectric properties. Their construction relies on the pure mineral perovskite. It is comparatively low-cost in comparison with silicon and different photo voltaic cell supplies, which makes them engaging.

Despite their promising potential, perovskite photo voltaic cells face two main obstacles proper from the beginning gate. An enormous situation is the effectivity of photo voltaic conversion. The first technology of perovskite photo voltaic cells started to appear in 2009 with a photo voltaic conversion effectivity of solely 3.8%, effectively beneath the standard effectivity of normal silicon photo voltaic cells.

Another situation is a bent to degrade the encompassing circumstances after only a few minutes. That appears to place perovskites out of the working for industrial growth, besides that science loves a problem.

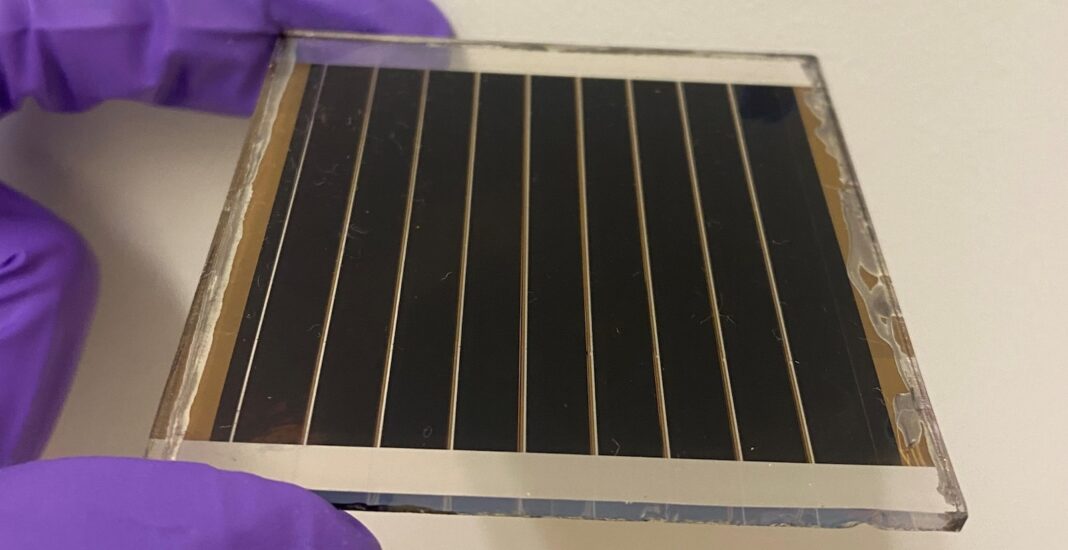

In the newest information, on March 4 a analysis staff primarily based at École Polytechnique Fédérale de Lausanne (EPFL) in Switzerland reported the best conversion effectivity for a perovskite photo voltaic module but licensed. They hit an preliminary licensed mark of 23.3% and the photo voltaic module stabilized at a conversion effectivity of twenty-two.97%.

For these of you on the go, the analysis staff additionally described how they tweaked their perovskite formulation to stop degradation and enhance sturdiness. In distinction to the restricted lifespan of first-generation perovskite photo voltaic cells, the EPFL staff reported that their perovskite photo voltaic module maintained 94.66% of its preliminary effectivity after publicity to steady one-sun illumination at room temperature for 1,000 hours. (full particulars can be found within the journal NATURE beneath the title, “Dopant-additive synergism develops perovskite photo voltaic modules”).

“Our method holds nice promise for bridging the benchtop-to-rooftop hole and advancing the manufacturing and commercialization of large-area perovskite photovoltaics,” the staff concluded.

More & Higher Perovskite Solar Cells

Extending the lifetime of a perovskite photo voltaic cell will also be a option to obtain cost-effectiveness, even when the photo voltaic conversion effectivity is lower than optimum. A analysis staff primarily based at Brookhaven National Laboratory within the US, for instance, reported the potential for perovskite photo voltaic cells to realize a 30-year lifespan with a photo voltaic conversion effectivity of 17.4%.

Lowering manufacturing prices is one other approach. On May 6, the University of California – Santa Barbara described some vital developments within the space. “Perovskite photo voltaic cell manufacturing additionally has the potential for a smaller carbon footprint than silicon photovoltaics, which require excessive temperatures and a clear surroundings,” the college defined. “As such, the manufacturing of those cells entails high-temperature annealing and troublesome post-treatment steps, which decelerate manufacturing and make it troublesome to include them into on a regular basis issues.”

Researchers on the college have developed a brand new perovskite “ink” that accommodates a streamlined, power environment friendly, room-temperature fabrication course of. Their new formulation eliminates the thermal annealing and post-treatment steps, that are described as the 2 longest parts in perovskite photo voltaic cell manufacturing.

“The staff’s innovation not solely simplified the manufacturing course of but additionally elevated materials effectivity from beneath 20% to 24.4%,” UC-Santa Barbara reported. Although the 24.4% mark didn’t hit the excessive bar established by EPFL, in accordance with the college it was the primary to exceed the 20% threshold for perovskite photo voltaic cells produced at room temperature.

The Roll-To-Roll Factor

If you get that ink factor proper, that is the important thing to the glowing inexperienced way forward for low-cost perovskite photo voltaic cells. Unlike standard, inflexible silicon photo voltaic cells, perovskite photo voltaic cells might be made out of an answer and sprayed, painted, or printed on a wide range of surfaces, together with versatile surfaces.

In explicit, perovskite photo voltaic cell followers are the eyeballing roll-to-roll printing know-how for prime quantity, quick throughput fabrication. The case for roll-to-roll perovksite printing was summarized on May 11 within the journal Communication in Nature by Ershad Parvazian and Trystan Watson of Swansea University.

“In a Roll-to-Roll system, so long as your enter supplies are constantly elevated, manufacturing ought to proceed indefinitely,” they stated. “In its easiest type it affords the premise of Ink-IN / Solar module-OUT.”

That’s not so simple as it sounds. In addition to itemizing the advantages of roll-to-roll printing, Parvazian and Trystan additionally define the challenges of bench-to-rooftop. “In distinction to the managed circumstances of laboratory-based spin coating within the glovebox or beneath a fume hood, R2R coating is carried out on a bigger scale in open area and requires meticulous administration of coating parameters,” they advise.

“The challenges intensify throughout the drying and annealing phases, the place sustaining a fragile stability of temperature, air circulation, and line velocity is important to keep away from defects,” they added.

Perovskite Solar Cells One Step Closer to the Roof

Despite the challenges, the US Department of Energy is likely one of the pioneers of roll-to-roll printing.

Back in 2017, the Department of Energy gave a $2 million award to New York startup Energy Materials Corporation to enhance perovskite photo voltaic cell sturdiness whereas deploying high-speed roll-to-roll printers. In an fascinating twist, the corporate leased printers from Eastman Kodak, a legendary title in high-end movie manufacturing.

The Department of Energy apparently preferred what it noticed, as a result of it gave EMC one other award in 2019.

“These printers can coat 1,000 ft of movie per minute,” the Energy Department reported in 2020. “EMC hopes to coat the perovskite at 100 ft per minute, a velocity that may produce sufficient photo voltaic panels to generate 4 gigawatts of electrical energy per 12 months.”

“For context, the complete United States put in 2.5 gigawatts of residential photo voltaic in 2019,” they added.

EMC appears to have dropped off the information radar since then, though in 2022 the corporate was tapped for one more Energy Department award. The proposal was nonetheless shifting via the environmental overview course of on the time. Assuming approval, the award will help a one-kilowatt pilot manufacturing run, which goals to provide about two dozen perovskites “mini modules” measuring between 0.01 and 0.4 sq. meters, to check in real-world circumstances on the National Renewable Laboratory campus in Colorado. or Sandia National Laboratories in New Mexico.

CleanTechnica reached out to EMC for the newest updates. We are significantly considering the results of an settlement, signed between the main glass and supplies firm Corning and EMC in 2020, which goals to “deliver low-cost, high-performance perovskite photo voltaic photovoltaic panels and merchandise within the power business.”

Follow me @tinamcasey on Bluesky, Threads, Instagram, and LinkedIn.

Photo credit score: “A perovskite photo voltaic module with an lively space of 22.0 cm2 containing fluorinated anilinium for interfacial passivation,” (Cheng Liu, Northwestern University by way of EPFL).

Have a tip for CleanTechnica? Want to promote? Want to recommend a visitor for our CleanTech Talk podcast? Contact us right here.

Latest CleanTechnica.TV Videos

CleanTechnica makes use of affiliate hyperlinks. See our coverage right here.

[ad_2]

Source link