[ad_1]

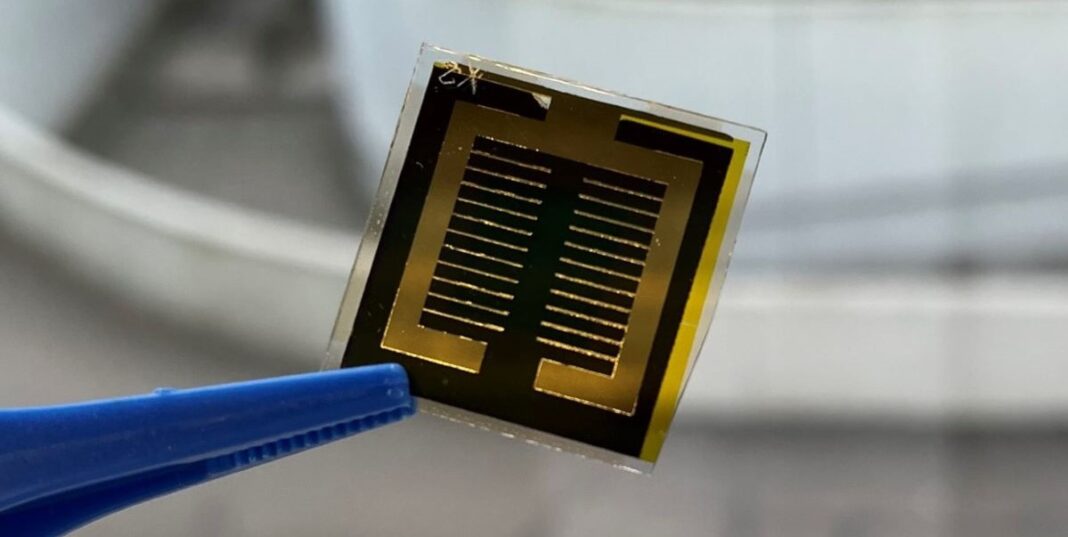

Researchers on the Karlsruhe Institute of Technology (KIT) have developed a scalable two-step evaporation and inkjet course of for perovskite thin-film photo voltaic cells. The new approach is reported to have the ability to produce champion cells with the identical effectivity as that produced by the spin coating course of.

A analysis group from the Karlsruhe Institute of Technology (KIT) has developed a scalable two-step course of for natural perovskite thin-film formation with potential functions in textured substrates.

The course of, described as a scalable and dependable approach for high-quality perovskite deposition, combines using an evaporated lead iodide layer with inkjet-printed natural perovskite precursor supplies.

“It is a problem and an amazing achievement to lift the efficiency of photo voltaic cells primarily based on evaporated lead iodide to the identical efficiency degree as gadgets with a spin-coated lead iodide scaffold,” mentioned corresponding lead writer, Raphael Pesch. pv journal, added that the workforce was in a position to tailor the porosity with a reasonable dimethyl sulfoxide (DMSO) vapor therapy. “We discovered early on that the porosity of the lead iodide in step one was vital for conversion in our two-step manufacturing course of.”

The course of can be mentioned to point out excessive reproducibility and potential for conformal development of textured silicon, and that gives movies with out drying results and poisonous solvents.

With the proposed approach, movies are deposited utilizing a Pixdro LP50 inkjet printer from the German provider SÜSS, with a Sapphire QS-256/10 AAA print head, with 16 occasions extra nozzles than of the everyday print heads utilized in labs for any such software. “This not solely helps improve droplet-surface interplay time, which is important to stop large-area drying results but in addition reduces the potential for pinholes,” says Pesch.

Referring to the Sapphire print head used within the research, KIT’s next-generation PV group chief, Ulrich W. Paetzold, identified that it is also used with bigger printers, such because the n.jet lab from Notion Systems, which may print locations. of 0.61 x 0.61 sq. meters at a velocity of two meters per second.

Paetzold emphasised the fee effectiveness of the method. “The natural precursor supplies wanted for constructing perovskite photo voltaic cells may be very costly,” he added. “While the fabric yield tends to be low when vaporized, inkjet printing allows us to realize near-perfect materials yield of almost 100%.”

By optimizing the printing parameters, the group achieved the champion machine with an effectivity of 18.2%, which is thought to be “the identical as its spin-coated counterparts”.

“We have been very shocked within the lab to see the numerous impact of this extra step on the efficiency of the cells,” mentioned Paetzold. pv journalstating that there’s nonetheless some work to be achieved to surpass the lab-based spin-coating course of.

“The spin-coated reference machine is even higher in efficiency in comparison with scalable processes,” mentioned Paetzold. The finest outcomes of this research are attributed to the morphology of the lead iodide skinny movie and the chosen decision of the printing course of, in addition to the intermixing and stoichiometry step carried out by the DMSO vapor therapy to extend the lead iodide porosity.

The novel approach is described within the paper “Hybrid Two-Step Inkjet-Printed Perovskite Solar Cells,” which was just lately revealed in RRL Solar.

Looking forward, the workforce will work to combine the manufacturing strategy of tandem gadgets and huge space gadgets. “The final aim is to course of full-size wafer silicon backside cells,” Paetzold mentioned.

This content material is protected by copyright and is probably not reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link