[ad_1]

Increasing the ability conversion effectivity of a photo voltaic module from 23.30% to 24.16% within the eyes of an individual who will not be aware of vitality issues, or the photovoltaic business, could appear to be nothing’ y issue improvement.

For these working on this sector, nevertheless, these outcomes are clearly an enormous leap in the direction of higher performing photovoltaic initiatives and a decrease stage value of vitality (LCOE ), if the module producers can scale up the mass manufacturing know-how with out being unmanageable. improve in manufacturing prices.

Huasun achieved this consequence between March and November 2023, not less than from an effectivity perspective, with HJT photo voltaic panels seeing a rise in energy output from 723.97 W to 750.54 W, which there’s a certification physique TÜV SÜD that verifies the outcomes.

The Himalaya G12-132 module consists of bifacial micro-crystalline G12 HJT cells with 20 busbars, independently developed by the Huasun Xuancheng Phase IV HJT Cell Project.

Cost versus effectivity

The firm acknowledges that there’s a tradeoff between excessive effectivity and decrease prices however is assured that main hurdles may be overcome quickly.

“We have arrived [at] a silver (Ag) paste consumption stage of round 16 mg/W,” in line with the corporate’s CTO, Wenjing Wang. “If we need to improve the effectivity much more, we have to use a slower technique of plasma enhanced chemical vapor deposition (PECVD) and several other Ag pastes. We can attain the next common effectivity in mass manufacturing, like 26%, and the module energy may even attain 725 W. But that requires extra course of tools and extra Ag paste consumption.”

In addition, the corporate seeks to scale back electrode prices and makes use of standardized manufacturing options equivalent to copper (Cu) plating, Ag/Cu pastes, wavelength conversion encapsulant movie, butyl rubber sealing know-how, wafer reducing know-how, and novel chain sort wafer gettering.

New cell structure

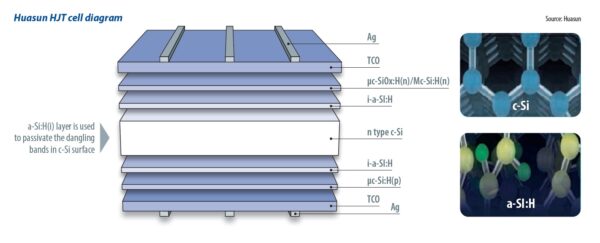

The HTJ photo voltaic cell know-how developed by Huasun doesn’t use conventional monocrystalline wafers, however n-type wafers based mostly on microcrystalline silicon. This materials, broadly utilized by thin-film photo voltaic cell makers, has the benefit of excessive service mobility, as a result of presence of crystalline silicon (Si) grains within the microcrystalline materials, and low bandgap vitality.

In addition, Huasun has developed a wafer manufacturing methodology to make extra environment friendly use of obtainable ingot materials. “We can use the facet a part of an ingot, if we minimize the cylinder right into a sq. ingot,” Wang stated. “There is a facet left that we will use to get extra wafer items from the identical ingot. The facet half is normally despatched again to the Czochralski (CZ) furnace to rebuild new ingots, however we will additionally minimize the facet half to chop items to reuse in our HJT cell.

“We name this cell technology HJT 3.0, as a result of it differs from our earlier merchandise for utilizing solely microcrystalline silicon,” Wang stated, referring to the corporate’s latest product. “For our first technology, we used amorphous silicon (a-Si) skinny movie and for the second we used amorphous and microcrystalline.”

Compared to the second-generation gadget, the third-generation cell reveals as much as 1.0% greater effectivity within the lab, and as much as 0.3% greater effectivity in industrial manufacturing, in line with the corporate.

The cell additionally depends on carrier-selective passivating contacts (CSPCs) manufactured from micro-crystalline silicon monoxide. These contacts result in spatial decoupling of service technology and service separation within the cell and supply excellent passivation, higher service selectivity, and low contact resistivity.

The cell additionally options the so-called tremendous multi busbar (SMBB) know-how, which is an evolution of the multi busbar (MBB) normal and includes the usage of a dense community of busbars (normally greater than 10), which reduces resistance and improves shading tolerance.

HJT 4.0

As an organization that’s continually innovating and creating its know-how, Huasun has created a street map for its cells. Moving to HJT 4.0, the corporate will optimize the clear conductive oxides (TCO) layer and cut back the thickness of the silicon layer to 90 micrometers. To additional cut back prices, the corporate goals to scale back the quantity of silver required in every cell, with the last word objective of utterly eliminating silver within the transition to copper plating.

Wang stated the evolution to HJT 4.0 may also embrace a transition to zero busbar (0BB) know-how, which is able to pave the way in which to an effectivity of 26.0-26.5% in mass manufacturing. Beyond Huasun’s fourth technology plans, the corporate is already exploring the event of HJT+perovskite tandem cells that may attain 28% cell effectivity, with 800 W of energy capability.

The firm plans to confirm the tandem know-how of a 210 mm photo voltaic cell and to confirm the mass manufacturing tools for the perovskite cell, focusing on the mass manufacturing of tandem merchandise in 2025.

This article seems within the new Huasun Corporate Edition, launched on April 10, 2024. Read the total version right here.

This content material is protected by copyright and might not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link