[ad_1]

Researchers from Germany’s Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) developed fashions to judge and examine two round water methods in a 5 GW passive emitter and rear (PERC) photo voltaic cell manufacturing unit.

They declare that is the primary revealed “complete water mannequin” for a photo voltaic cell manufacturing unit.

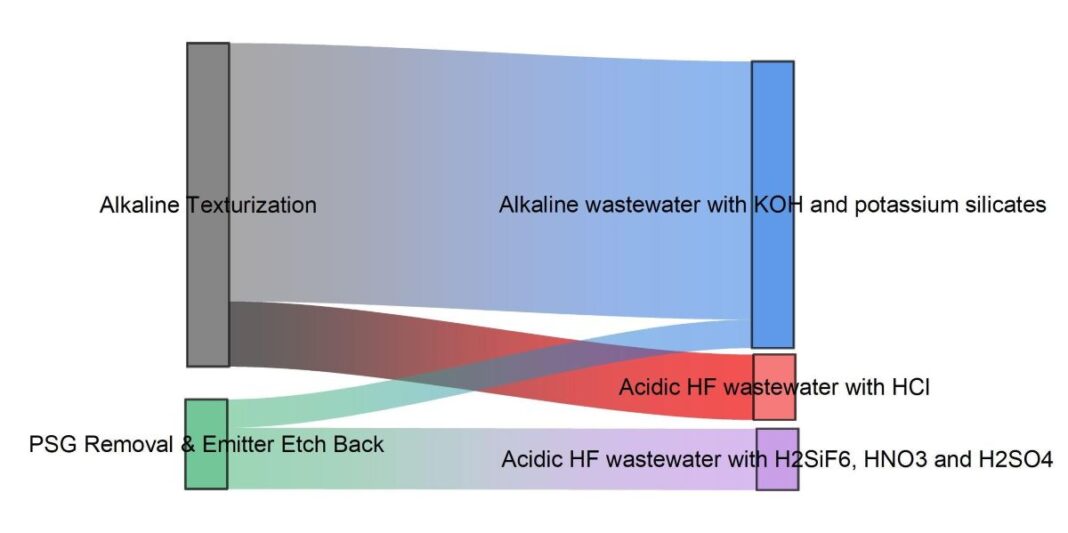

The group in contrast two eventualities of freshwater and waste stream in a water technique in a standard PERC cell manufacturing plant. The first state of affairs, referred to as low contaminated wastewater (LCR), reclaims washing water in order that it isn’t immediately discharged in accordance with laws. “In addition, some waste streams are used as recent water for downstream functions,” the researchers mentioned.

The second state of affairs, referred to as minimal liquid discharge (MLD), reduces the quantity of wastewater leaving the manufacturing unit as a lot as attainable, whereas figuring out and eradicating attainable substances from the wastewater, in accordance with the group.

For every state of affairs, a cost-benefit evaluation and life cycle evaluation (LCA) was completed utilizing the Umberto 11 software program, which is commonly used to investigate the environmental impacts of firms and merchandise, and the life cycle stock Ecoinvent database. The evaluation additionally depends on a particular materials stream mannequin, environmental evaluation, and complete price of possession (TCO) calculations.

“A basic environmental impression evaluation is required to find out if the proposed options obtain a internet environmental enchancment for the photo voltaic cell manufacturing system,” mentioned group. “The outcomes present that for the analyzed eventualities 38% and 79% of the water consumption and 40% and 84% of the oblique discharge of wastewater within the cell manufacturing unit might be saved by the LCR and MLD strategies , the truth is.”

In addition, price reductions of 0.5% and 0.7% from cell manufacturing had been recognized for the LCR and MLD methods, respectively. “Compared to the reference state of affairs, the proposed round water methods supply vital water and wastewater financial savings,” mentioned the group.

Several sorts of water and waste administration applied sciences are thought-about, bearing in mind price, vitality demand, operational threat and complexity. Only water recycling applied sciences which might be commercially accessible and particularly suited to the chemical traits of PV wastewater are thought-about, akin to reverse osmosis, calcium fluoride precipitation, and ultrafiltration applied sciences.

The group additionally gathered loads of information for every of the steps within the manufacturing of PERC photo voltaic cells. Other associated constraints embody a throughput of 2819 m2 cell per hour, and merchandise with the next traits: 160 µm thickness, 244.32 cm2, 5.37 W, and 22% cell energy conversion effectivity.

Several instruments are used to create state of affairs fashions. For mixing streams, evaporation, precipitation and neutralization reactions and utilizing chemical substances, the group used phreeqc software program, which is a pc program for speciation, batch-reaction, one-dimensional transport, and inverse geochemical calculations. Solutions for evaporation processes are modeled within the SIT.dat database for prime salt options. Membrane processes are simulated with DuPont WAVE water remedy design software program. Water and wastewater stream fashions are additionally proven, together with water restoration processes.

As for the life cycle impression evaluation (LCIA), the EU Environmental Footprint, Version 3.0, is used, and the environmental impression of a cell manufacturing rating has been achieved. It decreased by 0.4% for LCR and three.2% for MLD.

“The life cycle price evaluation carried out reveals that such applied sciences are economically viable for this utility, however the costs of vitality, water and waste have to be fastidiously assessed,” mentioned the lecturers, which provides {that a} discount in the price of internet cell manufacturing of € 0.025 / W and € 0.035 / W is achieved for the LCR and MDL methods, respectively.

“The reductions within the environmental impression of the cell manufacturing unit are estimated from -1.4% to 34.3% for the completely different impression classes, with a major discount within the ecotoxicity of freshwater, freshwater and ocean eutrophication for comparable round water methods,” the group defined.

The researchers supplied capital expenditure (CAPEX) and working expenditures (OPEX) for every of the 2 round water methods, noting that LCR’s complete vitality consumption was “comparatively low” with “very low CAPEX and OPEX ” case. They additionally noticed that, in comparison with the reference case, no useful resource restoration was obtained apart from water.

In their evaluation of the MLD state of affairs, they famous that it requires excessive thermal vitality and better CAPEX and OPEX for the mandatory equipment. As such, they famous that MLD can scale back recent water by 79%, and scale back wastewater by 84%, leading to annual financial savings in recent water and waste prices, in addition to the chance to recuperate “invaluable merchandise” to be used in different industries.

Looking forward, the researchers see the adoption of tunnel oxide passive contact (TOPCON) and heterojunction (HJT) factories as “many waste streams which were analyzed equally.” A demonstrator setup is really helpful, “to validate the estimated financial savings as many technical challenges have to be overcome.”

The new idea of water circulation is offered within the research “Circular water methods in photo voltaic cells manufacturing,” revealed in Solar Energy. The research is a collaboration of researchers from Fraunhofer ISE, RENA Technologies GmbH, Technische Universität Berlin, and the Fraunhofer Institute for Building Physics.

This content material is protected by copyright and might not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link