[ad_1]

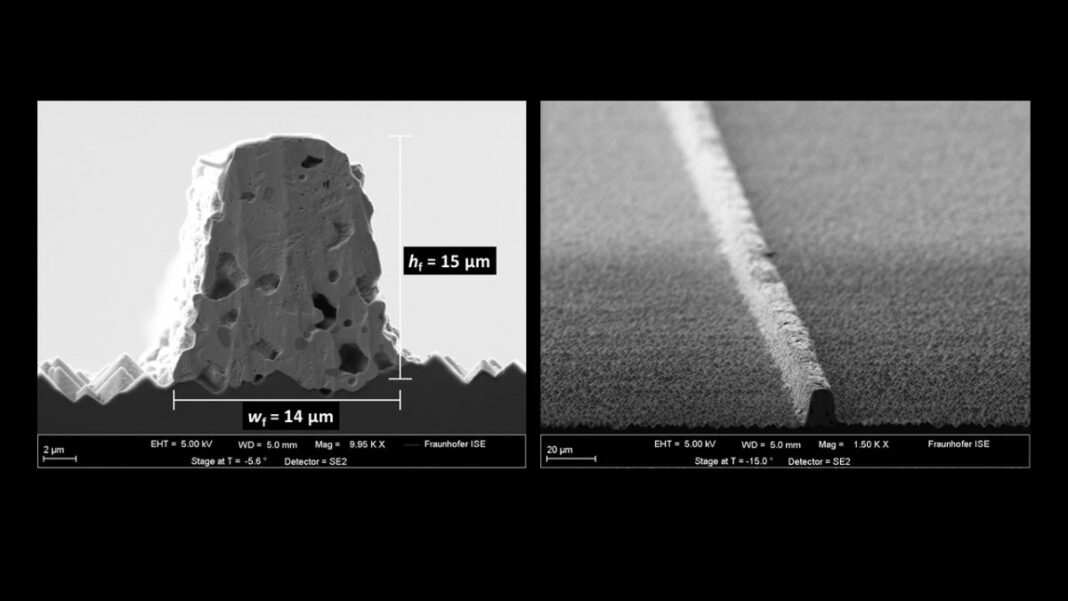

Finger cross-section shut up (l) large angle view (r)

Image: Fraunhofer ISE

Researchers from Germany’s Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) have developed a reproducible technique to supply ultra-fine contact fingers measuring 14 µm. They utilized the passive emitter and rear cell (PERC) cell fabrication course of with the purpose of decreasing silver consumption with out compromising machine efficiency.

“The energy conversion effectivity is 23.4%, verified and confirmed by the Fraunhofer ISE CalLab,” mentioned the analysis undertaking supervisor Elmar Lohmüller. pv journaladded that the Fraunhofer group has a 30-year observe file in optimizing PERC processes.

The outcome represents an inner record-breaking achievement after the group’s beforehand reported 20 µm entrance aspect contact milestone, based on Andreas Lorenz, who heads the PV printing expertise group at Fraunhofer ISE.

The group used a commercially accessible PERC silver paste, on a display printer from German tools supplier ASYS Automatisierungssysteme. The display printer depends on a wonderful mesh display offered by Asada Mesh Co. Ltd. in Japan.

Looking forward, Lorenz sees room for additional improvement to cut back silver consumption by additional decreasing the width of the finger and by changing the silver paste with different supplies, similar to of copper, for numerous cell applied sciences with excessive effectivity, together with tunnel oxide passivated contact (TOPCon) , silicon heterojunction and perovskite tandem photo voltaic cells.

The analysis shall be offered on the forty first European Photovoltaic Solar Energy Conference (EUPVSEC) in Vienna in September. The analysis undertaking, referred to as “Guten Morgen”, is funded by Germany’s Federal Ministry of Economic Affairs and Climate Action (BMWK).

Fraunhofer ISE has collaborated with ASYS Automatisierungssysteme on photo voltaic cell metallization initiatives previously in addition to with different companions to develop processes that scale back silver consumption.

This content material is protected by copyright and is probably not reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link