[ad_1]

The National Renewable Energy Laboratory has developed a proof of idea for a technique to take away polymers from photo voltaic panel manufacturing to allow extra environment friendly recycling.

From pv journal USA

Solar panels are extremely recyclable, however utilizing skinny plastic layers to cowl photo voltaic cells may cause challenges to recycle precious supplies like silicon or silver successfully.

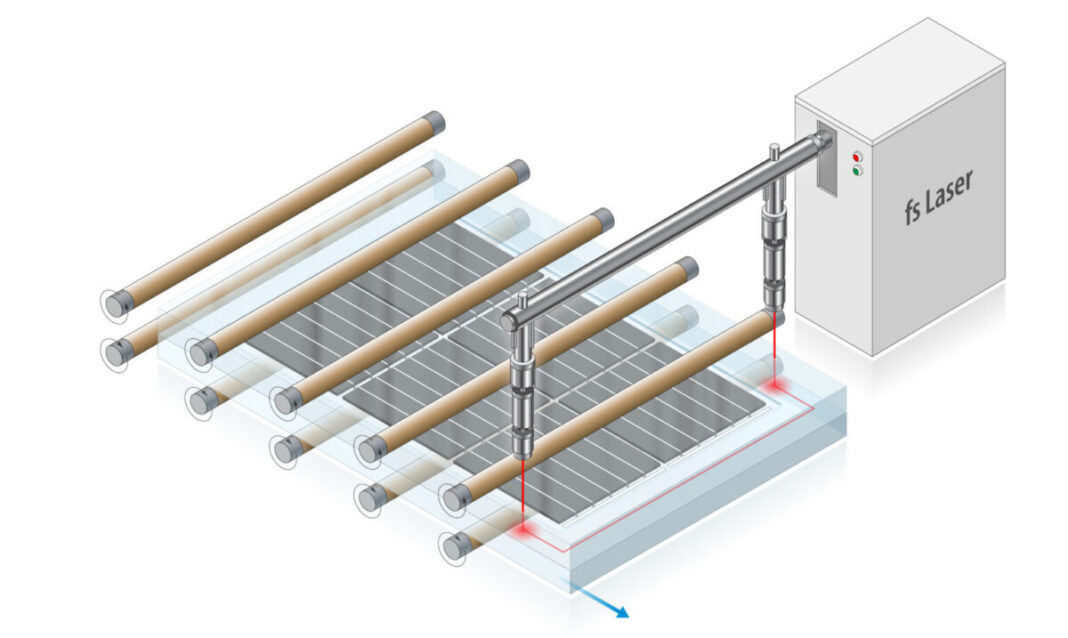

The US Department of Energy’s National Renewable Energy Laboratory (NREL) has developed a proof of idea that helps reduce using polymers by making direct glass-to-glass welds in photo voltaic cells.

The methodology makes use of femtosecond lasers, a sort of infrared laser that focuses power on a really brief time scale with a laser pulse. The laser creates hermetically sealed glass-on-glass welds. Femtosecond lasers at the moment are utilized in medical eye procedures akin to cataract surgical procedure right now.

Laser welds will eradicate the necessity for plastic laminates that make recycling harder. At the top of their helpful life span, modules product of laser welds might be damaged, and their glass and metallic wires might be recycled and the silicon reused.

“Most recyclers will affirm that polymers are the primary situation by way of limiting the recycling course of,” mentioned David Young, senior scientist and group supervisor for the High-Efficiency Crystalline Photovoltaics group in Chemistry. and Nanoscience division at NREL.

NREL examine was printed on IEEE Journal of Photovoltaics. The authors say that the laser is cell materials agnostic, which can be utilized in silicon, perovskites, and cadmium telluride, amongst others, as a result of the warmth from a extremely centered laser is proscribed to a couple millimeters. The researchers say that the welds inside the glass are basically as robust because the glass itself.

“As lengthy because the glass would not break, the weld will not break,” mentioned Young. “However, the absence of polymers between the glass sheets requires welded modules which might be extra inflexible. Our paper reveals that within the appropriate mounting and modification of the embossed components of the rolled glass , a welded module might be stiff sufficient to move a static load take a look at.

A unique sort of edge sealing utilizing nanosecond lasers and a glass frit filler was beforehand tried, however the welds proved too brittle to be used in outside module designs. Femtosecond laser welds provide superior power with airtight sealing at a compelling price, NREL mentioned.

The analysis was carried out by the Durable Module Materials Consortium, which goals to increase the helpful lifetime of photo voltaic panels to 50 years or extra.

This content material is protected by copyright and might not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link