[ad_1]

An worldwide analysis group is investigating how thermoelectric subcooling will be built-in right into a propane warmth pump to scale back the ability consumption of vapor compression techniques. Their work exhibits that this mix not solely reduces energy consumption but in addition improves warmth pump efficiency.

An worldwide analysis group carried out a computational evaluation of propane (R290) vapor compression warmth pumps combining a thermoelectric subcooler (TESC) to scale back energy consumption in vapor compression techniques and located This mixture can improve the effectivity of warmth pumps by 12.29%.

on paper”Effect of thermoelectric subcooling on the COP and vitality consumption of a propane warmth pump,” printed in Applied Thermal Engineeringthe scientists defined that the mix of those applied sciences was discovered to be very helpful for cooling techniques in earlier analysis and stated that the propane warmth pump may additionally profit significantly from thermoelectric subcooling.

TESCs are composed of thermoelectric modules (TEMs) and solid-state warmth engines that use electrons because the working fluid. TEMs are extensively used for digital cooling in units corresponding to private laptop processors, in addition to moveable meals and beverage storage techniques.

The computational mannequin is utilized to a residential propane warmth pump supposed to offer area heating.

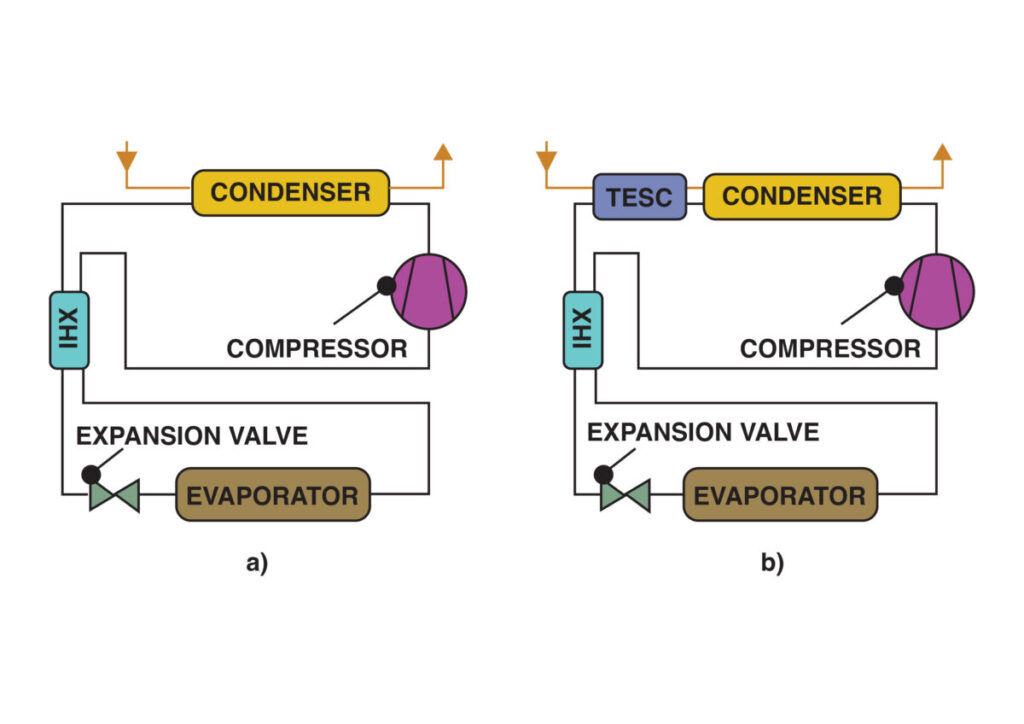

In the proposed system configuration, the TESC is situated between the condenser and the inner warmth exchanger (IHX). The water that must be heated goes by means of the TESC and subsequent to the condenser. In addition, the TESC absorbs warmth from the propane to offer subcooling on the condenser outlet, which advantages the operation of the vapor compression system.

“The temperature of the inlet water determines the inlet of the TESC, whereas the temperature of the skin water determines the inlet of the condenser,” the scientists defined. “Each of the blocks reveals completely different cold and hot sink temperatures, because the propane stream cools because it passes by means of the TESC system and the water stream heats up.”

The computational mannequin is reported to carry out an iterative course of that assumes the outlet temperature of every block and solves every block till the idea matches the operation of the block. It additionally calculates the outlet temperature of the propane and the outlet temperature of the water circulation, in addition to the COP and energy consumption of the TESC.

“The computational mannequin was developed in order that your complete warmth pump can present kW of heating capability,” defined the group. “For that function, the capability of the compressor is elevated with every decision to attain the kW of heating capability.”

In their simulations, the researchers thought of an ambient temperature between -20 C and 15 C, TEM voltage ranges from 0.5 V to 10 V, a thermoelectric system consisting of 1 to eight blocks, and two water inlet temperatures of 40 C and 55 C. They additionally take into account mass flows, heating capacities, compression ratios, compressor capacities, cooling capacities, temperatures, COPs, and vitality consumptions .

Their evaluation confirmed that the optimum TEM voltage degree is the important thing to maximizing warmth pump operation, and that increased voltage provides are counterproductive to vapor compression. It additionally exhibits that the very best COP enchancment of 12.29% is obtained when the ambient temperature is −20 °C and is achieved when the TESC is designed with 8 blocks composed of 16 TEMs.

“However, if the TESC system is diminished to half, which is shaped by solely 4 blocks (8 TEMs), the COP enchancment remains to be at 9.54%,” the group emphasised. “When the warmth pump is used for fan-coil area heating, the COP increments are 7.64 and 6.03 %, respectively.”

Further evaluation additionally exhibits that TESC may also enhance the seasonal coefficient of efficiency (SCOP) of the warmth pump by 9.98 % when an 8-block TESC system per kW of heating capability is built-in with water heating for typical radiators.

Academics now plan to construct a prototype system to substantiate the outcomes of the simulations. “Incorporating thermoelectric subcooling right into a propane vapor compression warmth pump has been proven to be very helpful by way of COP and vitality consumption,” they concluded. “Furthermore, thermoelectric techniques have confirmed to be strong, easy, versatile, dependable, low cost and straightforward to manage.”

The analysis workforce consists of teachers from the Public University of Navarre and the Jaume I University in Spain, in addition to the Silesian University of Technology in Poland.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.

Popular content material

[ad_2]

Source link