[ad_1]

The photo voltaic modules have an influence conversion effectivity of 10.8% and “satisfactory” tensile power and affect resistance, in line with their creators. The analysis group says it makes use of pure fiber composites as eco-friendly options to standard polyethylene terephthalate (PET) backsheets.

An worldwide analysis staff has developed a photo voltaic panel that makes use of a backsheet manufactured from pure zeolite-polyester resin as a substitute for the traditional polyethylene terephthalate (PET) backsheet.

The proposed innovation, in line with its creators, is meant to cut back the environmental affect of PET backsheets and to enhance the thermal and mechanical properties of the photo voltaic module. The pure fiber backsheet is produced by vacuum-assisted resin switch molding (VARTM), which scientists say ensures optimum thermal administration and insulation.

In the paper “Comprehensive examine of zeolitepolyester composite coated sheet for eco-friendly photo voltaic panels for improved panel efficiency and diminished panel temperature,” printed in scientific studiesthe analysis staff defined that using a pure fiber coated with zeolite-polyester resin is the important thing to bettering the efficiency and decreasing the buildup of warmth within the panels.

“The use of zeolite-polyester composites with pure fibers ensures glorious structural integrity, uniformity, and reliability,” the scientists emphasised. “While the preliminary value is greater, the long-term advantages embody decrease upkeep prices and higher efficiency, particularly in tough circumstances.”

The VARTM course of makes use of a vacuum to facilitate the circulate of resin right into a fiber layup contained inside a mould device coated by a vacuum bag. After the impregnation takes place, the composite half might be “cured” at room temperature with an elective post-cure generally carried out.

The researchers started the method by waxing the floor of the fabrication desk, marking the size, putting the spiral pipes, and securing with sealant tape. Then they use the movie to create a “clean” end for the again sheet and place different fiber mats on the movie. Then one other layer consisting of peel ply and a inexperienced mesh is positioned on prime, adopted by connecting the vacuum pipe to the spiral pipe with a T connector.

In addition, one feed port is positioned within the middle for single-layer fibers and two extra feed ports are positioned diagonally. Then, they put a vacuum cowl on the perimeter of the sealant tape. “The measurement of the again web page is 20 x 20 cm, and the thickness of the web page is maintained at 1.5-3 mm,” the researchers stated. “For every layer of given fibers, 90 g of zeolite and 135 g of polyester are used.”

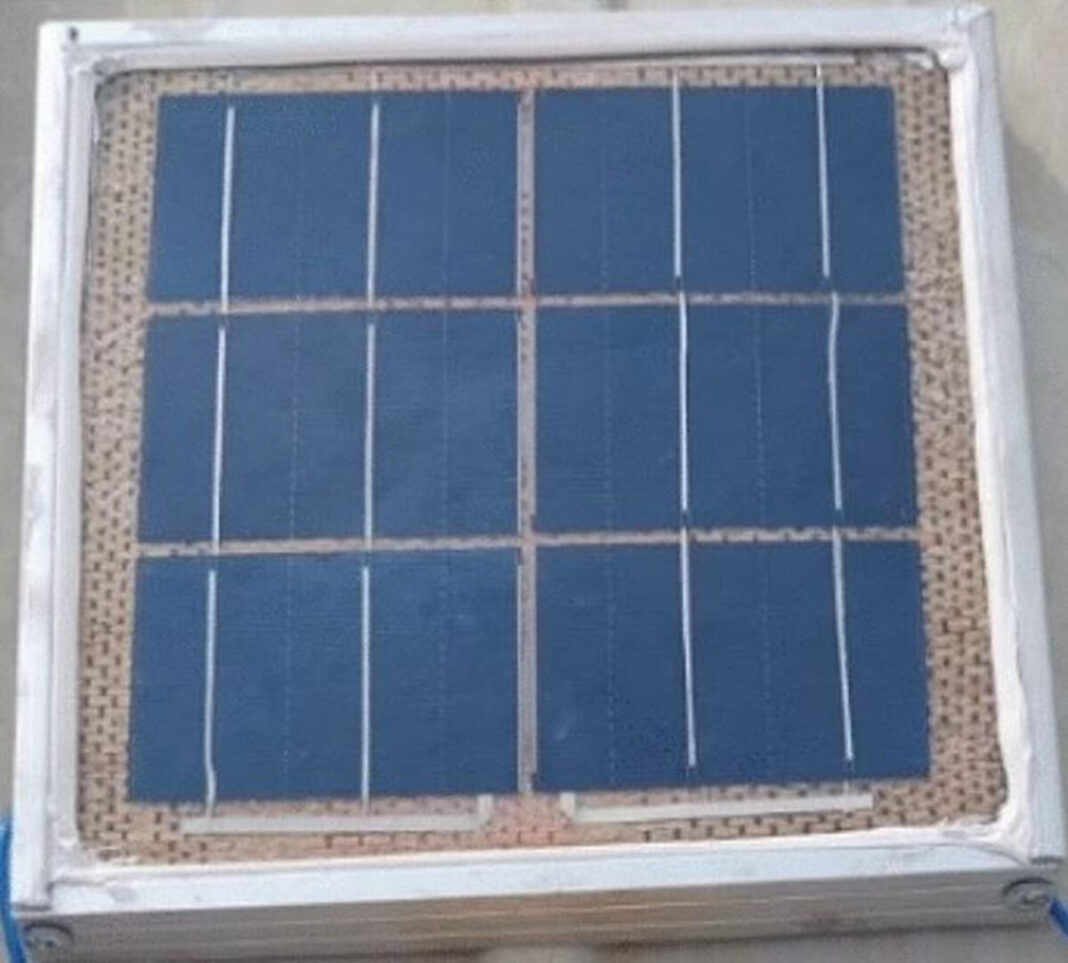

The group constructed a 4.5 W polycrystalline photo voltaic panel with Ecolam Max 3, a photo voltaic module automated laminator with a load and unload belt.

The 20 cm x 20 cm panel makes use of an aluminum body and cells organized in two columns, with every column linked to a bypass diode to type an unbiased string of cells.

According to the analysis staff, the coated model confirmed an 8% improve in voltage and a 6% improve in present circulate in comparison with typical panels, whereas the pure sisal panels confirmed 4% greater voltage and three% greater present. present.

“Coated pure sisal panels present a 12% improve in energy output, whereas uncoated pure sisal panels present a 7% improve in comparison with typical panels,” it additional defined. “The effectivity of the photo voltaic panels improved from 9.75% to 10.8% with a pure sisal coating and 10.2% with a pure sisal fiber backsheet.”

Academics additionally know that the manufacturing of sisal fibers emits about 60% much less CO2 and requires 50% much less power than PET backsheets. “Solar panels with sisal fiber sheets present enough tensile power and affect resistance and scale back the working temperature by 2-3 C, guaranteeing secure operation and decreasing warmth loss,” they added.

Looking forward, the group stated that sisal fiber-based again sheets might be “successfully” utilized in photo voltaic panel manufacturing to enhance efficiency and sustainability. “The implementation of pure fiber-reinforced zeolite-polyester composites in photo voltaic panels not solely addresses environmental issues but additionally paves the way in which for the event of high-performance, sturdy, and sustainable photo voltaic power options,” it concluded. .

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].

Popular content material

[ad_2]

Source link