[ad_1]

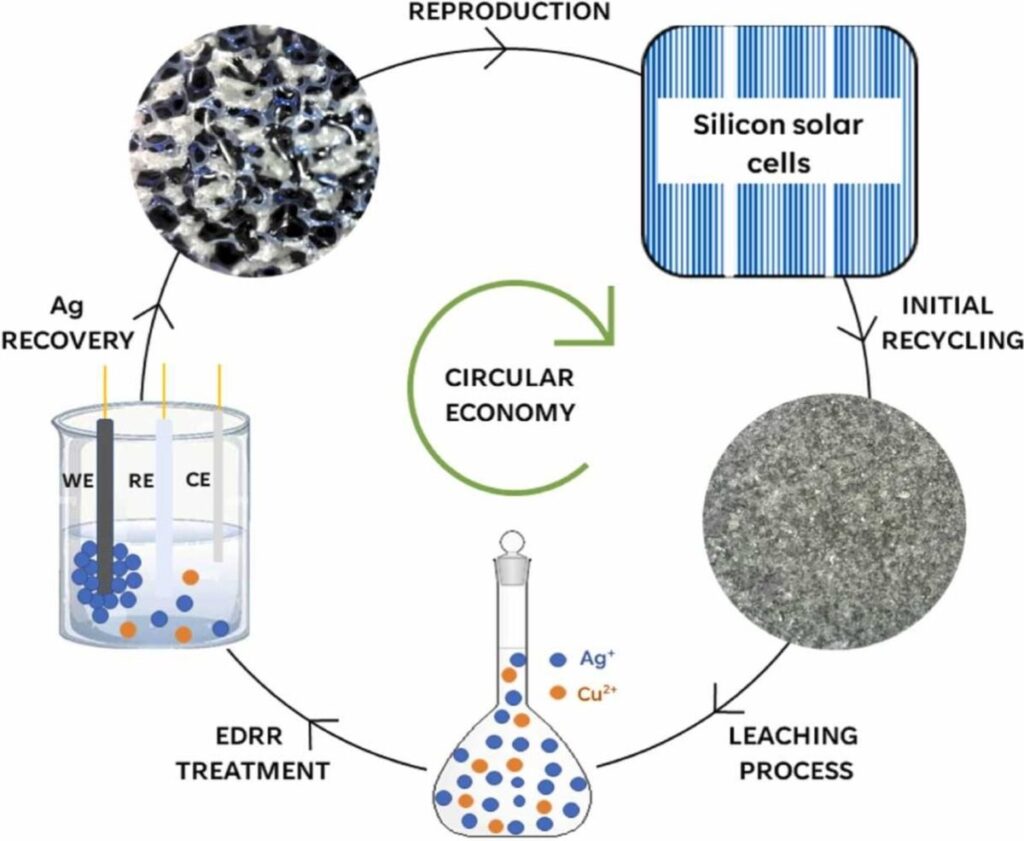

Scientists use hydrometallurgical and electrochemical processes to extract pure silver from photo voltaic cells. The proposed approach additionally makes use of a way often called electrodeposition-redox alternative, which is reported to extend the silver restoration charge.

Researchers from the University of Camerino in Italy have developed a brand new methodology to extract silver from end-of-life photo voltaic cells.

Combining hydrometallurgical and electrochemical processes, it’s reported that they obtained pure silver with an effectivity of 98%. Hydrometallurgical processes, or leaching, use aqueous options to extract metals, whereas electrochemical processes goal to make use of electrical currents to activate reactions in metals.

“The acquisition of uncooked supplies is essential for a lot of causes,” the teachers defined. “Conventional strategies of steel extraction, comparable to open-pit mining, could cause vital injury to the surroundings and neighboring ecosystems. Therefore, utilizing a steel restoration course of based mostly on industrial waste can scale back the affect In addition, steel restoration usually requires much less power than extracting metals from the ore, which ends up in decrease power consumption and decrease carbon emissions, particularly if the restoration charge is comparable or greater than conventional extraction strategies.

Due to the shut worth of the usual discount potential of silver and copper, the leaching of silver particles from PV waste is difficult. To overcome this, the researchers proposed a mixed base-activated persulfate and ammonia, with persulfate appearing as an oxidizing agent, whereas the system itself creates a protecting airtight layer of copper (II) oxide, which prevents self-leaching.

To take a look at the proposed course of, the researchers performed an experiment that consisted of various parameters for the leaching course of. It is the focus of ammonia (NH₃) in an answer, measured in moles per liter (mol/L); PV waste pattern, in grams per liter (g/L); potassium persulfate (PPS), in mol/L; and response time, in minutes. The temperature was stored at 25 C and the stirring charge at 300 rpm throughout all experiments.

Image: University of Camerino,

Environmental Technology & Innovation, CC BY 4.0

“The following circumstances had been chosen as the perfect: 0.5 M of NH₃, 0.2 mol/L of PPS, S/L ratio of fifty g/L, and response time set at 60 min,” defined the teachers. “Two further experiments had been carried out below these circumstances to test the reproducibility. When mixed with the 2 earlier assessments from the experimental design, a median of 85.0 ± 2.6% was achieved in a 95% confidence interval.

Despite these good outcomes, 85% of the obtained pure silver was thought-about inadequate by the analysis group, which determined to start out the electrochemical course of. Namely, the electrodeposition-redox alternative (EDRR) methodology utilizing the pulsed electrodeposition methodology. “This approach, beforehand reported within the literature, permits the restoration of extremely pure silver steel from hydrometallurgical leachate containing copper,” the staff defined.

The finest circumstances for silver restoration had been discovered with the EDRR methodology, which reportedly achieved an effectivity of 98.7%. “It is price mentioning that this methodology proves to be selective within the restoration of silver and doesn’t require any chemical addition. This distinctive function makes this methodology aggressive in comparison with standard processes,” concluded the scientists.

The novel methodology and the outcomes of the experiments are offered in “Silver restoration from silicon photo voltaic cells waste by hydrometallurgical and electrochemical approach,” printed in Environmental Technology & Innovation. The research was carried out in collaboration with ORIM, an Italian firm specialised in steel restoration from stable waste.

This content material is protected by copyright and might not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: editors@pv-magazine.com.

Popular content material

[ad_2]

Source link