[ad_1]

From pv journal 06/24

Across the MENA area, photo voltaic installations see a 23% improve by 2023, in line with the Middle East Solar Industry Association (MESIA). Growth is ready to speed up, with MESIA predicting that the present 32 GW will grow to be 40 GW by 2024, and 180 GW by 2030. In December 2023, Saudi Arabia raised its 2030 photo voltaic goal to 130 GW, which might require and greater than 20 GW of annual installations, additional.

The area’s photo voltaic business has to date targeted on large-scale PV, with the United Arab Emirates, Egypt, and, extra just lately, Saudi Arabia now internet hosting a number of the world’s largest photo voltaic installations. Although the area is not any stranger to building mega-projects, the native photo voltaic business remains to be younger and hosts restricted infrastructure to help the event and profitable operation of large-scale photo voltaic vitality tasks. When it comes to making sure high quality and long-term efficiency in a harsh desert surroundings, the MENA area has to date seen restricted talent improvement to supply lab-based product testing or on-site providers similar to in drone thermography or electroluminescence (EL). ) imaging.

“If we have a look at the providers supplied, whether or not they’re associated to commissioning, post-installation inspection, or every other on-site testing, all of them require a really sturdy native infrastructure, ” mentioned Mohamed Saady, head of technical providers and product administration for MENA at Chinese panel maker JinkoSolar. That limitation, he added, can result in longer response occasions and elevated prices related to buying the mandatory experience from afar.

Quality assurance

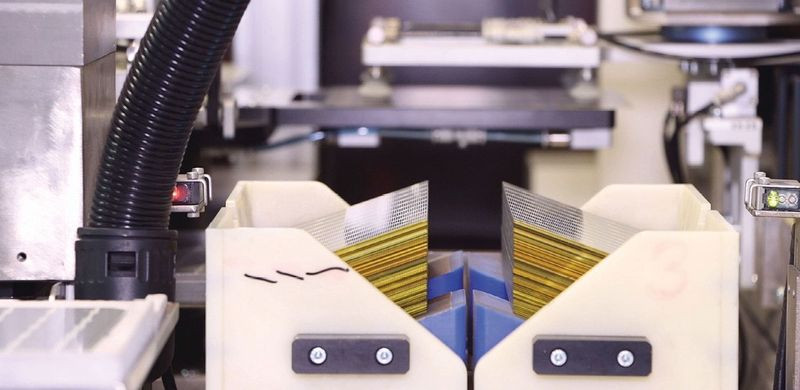

PV manufacturing has additionally, to date, seen solely restricted improvement within the MENA area, and could also be a prerequisite for additional improvement in testing and different help industries. “Most reliability testing is completed by suppliers and in labs near manufacturing,” explains Jörg Althaus, director for high quality assurance and engineering providers on the consultancy Clean Energy Associates (CEA). “Local testing is significant as a result of it is advisable to construct that experience however it will not occur till we see regional manufacturing progress.”

At the identical time, producers lively within the MENA area have confirmed that the native infrastructure for product and system testing can save them plenty of money and time and encourage extra manufacturing capability within the area.

“We do full high quality testing in-house however generally it is advisable to work with third events on prolonged testing or calibration,” mentioned Mohammed Shehadeh, chief know-how officer of Jordanian module producer Philadelphia Solar. “And it prices us so much to ship modules to Europe, China, or the US.”

The present lack of native testing infrastructure may gradual producers’ progress in adopting the brand new know-how, Shehadeh mentioned, as modules have to be despatched to distant testing amenities for certification. each time there’s a change or improve. “There’s a value to all of this transport and a really lengthy lead time that would delay us from attending to market early with a strong new product. A regional facility would undoubtedly make it simpler in that course of.”

The Gulf Renewables Laboratory (GRL), primarily based in Dammam on the Gulf Coast of Saudi Arabia, is a three way partnership between the US-based testing group UL [Underwriters’ Laboratories] and Saudi-headquartered GCC Lab, and is among the first within the area to be licensed by IECEE – a physique of the International Electroctechnical Commission – to check PV modules and techniques to numerous business requirements.

“Over time, we anticipate extra factories to return to Saudi Arabia, attracted by the numerous native content material tasks and packages adopted by the Ministry of Energy,” mentioned Saeed Balhaddad, normal supervisor of GRL. “We anticipate elevated demand for content material testing and certification.” He added that some builders are conducting pattern testing of imported modules upon arrival in Saudi Arabia, which is beneficial by regulators and different business consultants.

Although GRL presents lab testing providers, Kamalakannan Jayachandran, a renewable vitality engineer at GRL, confirmed that since its inception, in 2017, the lab’s enterprise has targeted on on-site try. “Currently in Saudi Arabia, greater than 4 GW of PV tasks have been put in and now we have repeated requests for energy efficiency exams, efficiency ratio, EL take a look at, and drone thermography,” mentioned he.

That demand is predicted to extend, with venture builders and homeowners including extra exams to make sure the long-term reliability of their properties.

“Some exams, similar to post-delivery inspection and deliberate capability exams, are new to the market and haven’t but been taken however they’ve been ordered by the builders and can quickly be applied in any respect websites,” mentioned Jayachandran.

Code of the desert

As nicely because the localization of amenities, testing particular to the cruel desert surroundings is one thing that’s more and more wanted by venture builders, each within the lab testing used to certify the modules and in on-site testing to establish discipline weaknesses. “Projects in Saudi Arabia or the MENA area typically require extra intensive testing that goes past the typical requirements, whether or not it is double or triple, and even various kinds of testing,” mentioned JinkoSolar’s Saady.

GRL created the so-called “desert code” for module testing which is a modified model of IEC 61215 primarily based on the identical take a look at processes however carried out with extra excessive parameters. In thermal biking, for instance, the place modules are repeatedly uncovered to excessive temperature modifications, IEC 61215 specifies 200 cycles from -40 C to a most temperature of 85 C. The GRL carry out 400 cycles and push the utmost temperature to 105 C. The 1,000 hours of damp warmth publicity specified by the IEC normal can be doubled, to 2,000 hours. “Within the IEC normal itself, there are clauses that say that to be able to meet a sure requirement for set up circumstances, you possibly can change the exams to a better degree,” mentioned Jayachandran. “In the longer term, this will probably be an actual sport changer for the certification of PV modules.”

Besides elevating the parameters of the present exams on this means, many consultants see the necessity for brand spanking new exams utterly. “For every venture in Saudi Arabia at present, we do plenty of testing for various combos of bills-of-materials, as a result of the IEC normal shouldn’t be sufficient and doesn’t meet the necessities of the PPA [power purchase agreement]”mentioned Jinko’s Saady, pointing particularly to different requirements similar to IEC 62892: 2019 and IEC TS 63126: 2020 that decide the rules for the qualification of PV modules, parts, and supplies for operation at excessive temperatures.

In the desert, sand abrasion presents one other potential difficulty that will not be adequately thought of in present exams. CEA’s Althaus says that whereas most tasks at present use glass-glass modules which are usually much less weak to sand, there should be a threat of dropping the transparency of the glass or harm to cables and containers. junction, and {that a} new normal could also be required. “None of the exams for sand abrasion make sense for merchandise that will probably be put in outdoors within the desert for 20 years,” he defined. “That’s the issue with the photo voltaic business; Modules are a long-lived product and many of the requirements that have been initially borrowed from different industries weren’t supposed for that sort of operation.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.

Popular content material

[ad_2]

Source link