[ad_1]

A serious concentrated solar energy Tower (CSP) venture in China has chosen Sulzer to provide the cold and hot molten salt pumps for the set up. The deliberate 100 MW web site is a part of a major renewable vitality program, pushed by the rising demand for sustainable vitality sources in China and all over the world. Sulzer’s experience and expertise on this sector has led to many profitable initiatives that present energy 24 hours a day from photo voltaic vitality.

Molten salts have been used within the nuclear business for almost 70 years and Sulzer has been concerned within the design and manufacture of pumps that transfer high-temperature fluids round cooling circuits. In reality, the corporate was concerned in pioneering the know-how out there within the photo voltaic business greater than 15 years in the past, which permits thermal vitality to be saved in a single day.

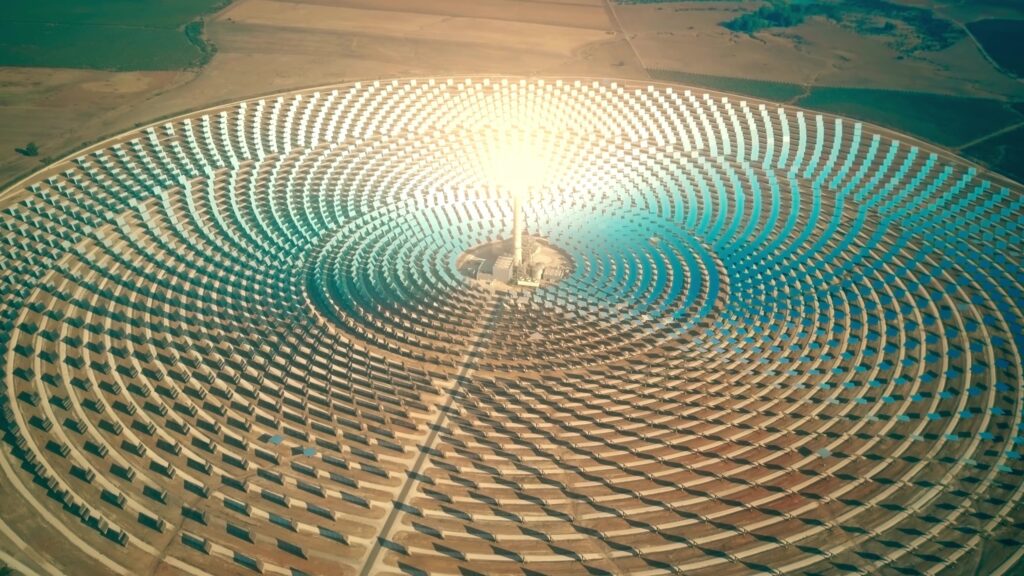

The molten salt is pumped into photo voltaic collectors (towers or parabolic mirror fields) the place its temperature rises from 300 °C to 600 °C. The excessive temperature salt is then saved in a tank and transferred to a warmth exchanger the place the thermal vitality is used to create steam that generates energy utilizing a turbine/generator. This circuit acts as a thermal battery, enabling photo voltaic crops to ship energy across the clock in good photo voltaic circumstances.

Sulzer has an extended observe report of delivering cold and warm molten salt pumps to photo voltaic installations all over the world, together with current initiatives in China. The 100 MW CSP Tower venture is the primary of its sort to make use of Sulzer pumps for each cold and warm circuits. The three chilly molten salt pumps will probably be geared up with 2.6 MW motors and prolong 18 meters under the bottom plate to the chilly molten salt tank. It will probably be paired with two warmth pumps, with all pumps manufactured at Sulzer’s Suzhou plant.

The most important problem of this venture is the elevated working stress required by the molten salt circuits. Areas with small outputs often function at round 50 bar, however this venture requires a 100 bar provide stress from the pumps.

Each pump is made to order and this venture needed to be engineered to fulfill the elevated stress and the low energy necessities. Compared to extra widespread, low stress pumps, there are various necessary factors, reminiscent of throttle bushing and bush bearing design, which must be fastidiously checked, correctly engineered and examined earlier than beginning. the manufacturing course of.

In this case, the end-user needs to attain particular targets within the supply of this venture. They need worldwide manufacturers to provide key tools, which is greatest made in China and value efficient in comparison with the competitors.

Sulzer was in a position to obtain all these objectives. The engineering of the bare-shaft pump will probably be achieved in Europe and the manufacturing will probably be an in depth collaboration between services in Belgium and China. In addition, the corporate will provide a complete assist bundle for merchandise delivered by an area service middle. By selecting Sulzer for cold and warm pumps, the top consumer can even streamline its spare elements stock.

As a part of the contract native Sulzer engineers are readily available to assist the set up and commissioning of the tools. Because of their peak, the pumps will probably be assembled on web site earlier than being put in in storage tanks.

This set up follows a number of different profitable initiatives in China for Sulzer together with three scorching pumps for an additional 100 MW CSP in addition to six scorching and 5 chilly pumps for a 42 MW parabolic trough set up.

About Sulzer

Sulzer is a world chief in fluid engineering. We focus on pumping, agitation, mixing, separation and software applied sciences for fluids of every kind. Our clients profit from our dedication to innovation, efficiency and high quality and from our responsive community of 160 class manufacturing services and repair facilities worldwide. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2023, our 13’130 workers generated income of CHF 3.3 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN).

www.sulzer.com

Manufacturing and Engineering Magazine | The Home of Manufacturing Industry News

[ad_2]

Source link