[ad_1]

A bunch of researchers investigated how high-temperature warmth pumps will be scaled up for industrial purposes and located that bigger setups promise greater effectivity. They additionally discovered that smaller setups present a greater coefficient of efficiency on account of design results.

A European analysis crew investigated the growing impact of high-temperature warmth pumps (HTHP) utilizing R1233zd(E) refrigerant and located that their dimension is a crucial issue within the coefficient of efficiency ( COP).

The group in contrast, specifically, the efficiency of two laboratory-scale HTHPs of various capacities to make legitimate basic statements concerning the challenges of upscaling. “It must be famous that the research focuses on reciprocating compressors. The growth of the conduct of different compressors stays to be investigated,” corresponding writer Jaromir Jessberger SPOKE pv journal.

“Studies normally give attention to an experimental facility and confirm measured experimental outcomes utilizing simulation fashions or literature knowledge,” the researchers mentioned. “However, as a result of giant variations between these experimental setups and industrial operations, an essential analysis query arises concerning the opportunity of immediately scaling up the laboratory outcomes to a bigger thermal capability.”

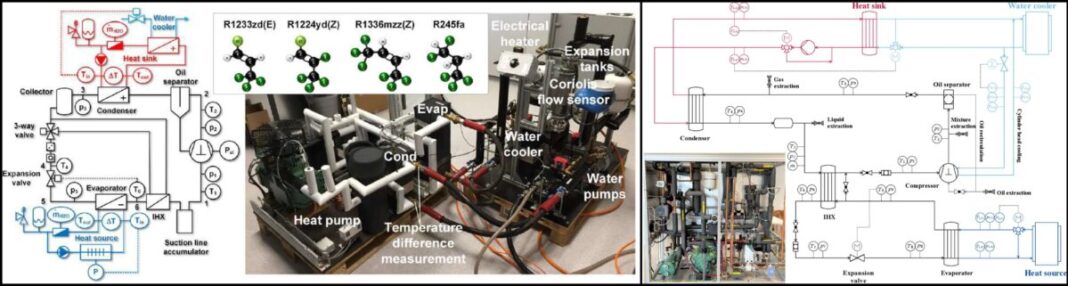

The analysis crew in contrast two HTHPs designed in earlier literature, one with a thermal capability of 11 kW (HTHP A) and one other with a thermal capability of 35 kW (HTHP B). They evaluated each for warmth switch traits, warmth lack of varied parts, compressor coefficient, and coefficient of efficiency (COP).

“The warmth pumps thought of present a excessive degree of part similarity, corresponding to a reciprocating compressor from Bitzer, plate warmth exchangers, and oil separators, which allow a thermodynamic comparability between them,” mentioned the teachers. “They each have a warmth pump cycle with a piston compressor and an inside warmth exchanger (IHX).”

Through their evaluation, the scientists discovered that wider setups promise greater effectivity. “Pinch level and temperature glides will be influenced by relative part sizing; scaling results corresponding to 15% greater warmth loss in small vegetation are possible attributable to a bigger floor ratio for warmth loss in heating capability,” they mentioned.

Also, as a result of completely different energy draw to friction ratio, the bigger HTHP B reveals a greater volumetric effectivity of 0-3.5% greater, in addition to a greater isentropic effectivity of 6%-8.7% . “At the system degree, small setups present a lot of the operations that time to a greater COP, which is a results of the design results. Considering the COP as a operate of the evaporation temperature, the efficiencies are in the identical trendline,” they added.

Finally, to additional discover a basic assertion about upscaling, the scientific crew additionally analyzed the conduct of over 200 knowledge factors of commercial HTHP. They additionally embody an evaluation of the techniques Carnot-COP, which is the utmost theoretical effectivity of a warmth pump.

“Using these knowledge factors, an affordable assumption for low constancy fashions, for the combination of HTHPs into vitality techniques or industrial processes, is to make use of a COP of 45% of Carnot-COP for a set of working circumstances,” they defined.

Their work was offered in “Experimental investigations on the results of temperature rise in high-temperature warmth pumps with R1233zd (E),” printed in International Journal of Refrigeration. The crew contains scientists from Germany’s University of Bayreuth and Switzerland’s Eastern Switzerland University of Applied Sciences.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link