[ad_1]

Sticky Solar Power is taking orders for industrial variations of its novel room-temperature cell interconnection system, which is reportedly well-suited for back-contact (xBC), perovskite, and heterojunction cell applied sciences.

Swedish stringer producer Sticky Solar Power has introduced that it’s taking orders for its industrial-scale room-temperature cell interconnection system based mostly on its tape resolution, as a substitute of soldering. Capable of making use of as much as 20 busbars at a time, the throughput ranges from 2,500 to three,500 connections per observe per hour.

The photo voltaic stringer helps lead-free interconnection and makes use of 60% much less silver than standard processes, in accordance with co-founder and CEO, Jonas Buddgård. “It will be built-in into any manufacturing line as a result of it’s made for batch or in-line manufacturing with a small manufacturing unit footprint of solely 6 m²,” Buddgård stated. pv journal. “Equipped with an elective layup, the dimensions will increase to about 10 m², relying on the output preferences.”

The preliminary goal prospects are European and US-based producers of back-contact (xBC), perovskite, heterojunction, and bifacial merchandise.

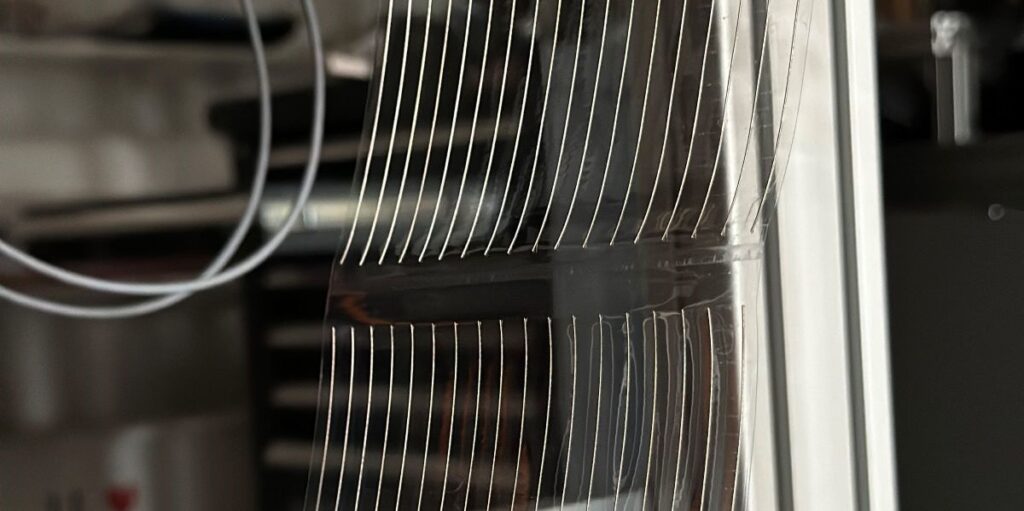

The Sticky Solar Power stringer is predicated on a tape resolution, that’s, the interconnection wires are hooked up to an adhesive tape which in flip is utilized exactly to the gear to the cell surfaces. The tape holds the wires and cells in place till the encapsulant lamination step. The machine eliminates single-cell soldering, successfully combining interconnection and lamination steps into one.

“With stringing carried out at room temperature, the very best required course of temperature for the tape resolution is as little as 150 C,” says Buddgård, noting that the gear can be utilized for as much as 24 hours at a time days, three hundred and sixty five days a 12 months. It works with each ethylene vinyl acetate (EVA) copolymer and polyolefin elastomers (POE) supplies.

“We make it competitively priced, in comparison with different European producers. Capital expenditure, recognized danger, and working prices are aggressive, that is the entire thought of the tape resolution,” added stated Buddgård.

While it’s effectively suited to low temperature cell processing as an alternative choice to standard soldering, the gear additionally affords advantages to monocrystalline passivated emitter rear cell (PERC) and tunnel oxide passivated contact (TOPCon) product producers. , resembling lowering the variety of steps. and fewer materials consumption, in accordance with the corporate.

Lower temperatures additionally imply decrease danger of photo voltaic cell cracking. It can even scale back warping or bending of back-contact photo voltaic cells.

Cell applied sciences supported embrace heterojunction, perovskite, perovskite silicon tandem, PERC and TOPCon, bifacial, and xBC designs. It helps normal codecs, resembling M2, M6, M10 and M12. The tape is utilized in back-contact mini-modules which have handed the IEC 61215 thermal biking exams.

This content material is protected by copyright and might not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: editors@pv-magazine.com.

[ad_2]

Source link