[ad_1]

Austrian researchers performed exams on thermoplastic polyolefin (TPO) encapsulant as an alternative choice to standard ethylene vinyl acetate (EVA) copolymer and polyolefin elastomers (POE) to research its use in glass-glass modules. They reported that each one TPO specimens outperformed EVA and POE, particularly the TPO-3.5 encasulants.

Austrian researchers have investigated the degradation potential of thermoplastic polyolefin (TPO) encapsulants to be used in glass-glass modules, as an alternative choice to standard ethylene vinyl acetate (EVA) copolymers and polyolefin elastomers (POE).

“TPO movies are at the moment used for area of interest merchandise, comparable to coloured double glass modules and constructing built-in PV-modules. Double glass modules require encapsulants with a decrease quantity of reactive by-product. In distinction to crosslinking EVA and POE encapsulants, TPO supplies enable ease of processing and recycling,” Martin Tiefenthaler, a researcher at Johannes Kepler University Linz (JKU), stated pv journal, added that TPO movies don’t include peroxide and don’t include vinyl acetate comonomer items, that are vulnerable to hydrolytic degradation.

In the examine, the crew ready double glass laminates, measuring 25 mm × 25 mm × 7 mm, utilizing three TPO movie adhesives, every with a distinct formulation, TPO-3.5, TPO-UV, TPO-F, and equipped by Austria’s Borealis. Two extra specimens made with EVA and POE have been used as requirements.

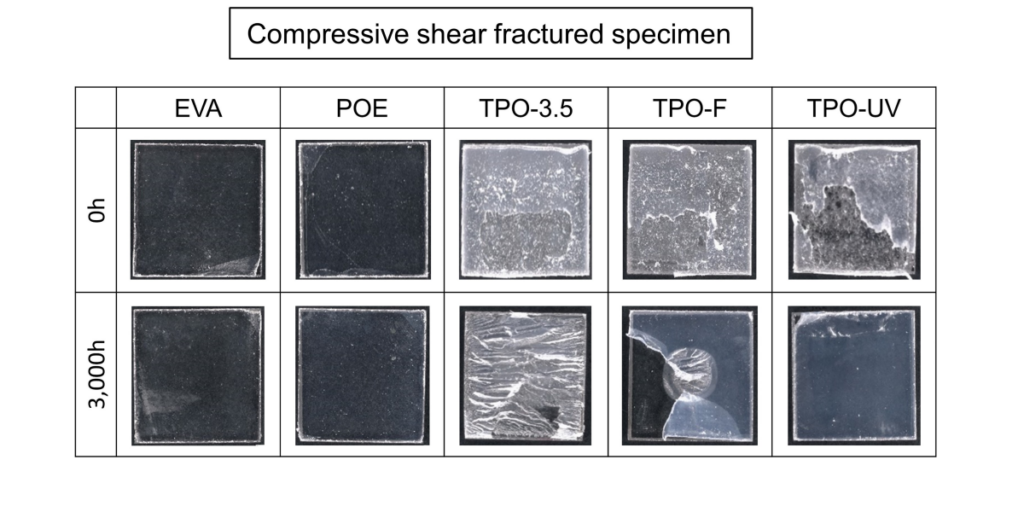

Before compressive shear testing, the experimental specimens have been uncovered to ultraviolet (UV) irradiation of 40 W/m2, temperature of 65 C, and relative humidity of 10 % for as much as 3,000 h. A visible, optical, mechanical, and chemical evaluation of the adjustments was made through the use of a number of devices, together with microscopy, UV-visible-near infrared spectroscopy, compressive shear testing, in addition to differential scanning calorimetry, Fourier remodel infrared spectroscopy and X-rays. photoelectron spectroscopy.

The crew analyzed and ranked the outcomes. They discovered that the best-performing TPO variation was TPO-3.5, adopted by TPO-UV, TPO-F, EVA, and POE. “While aged and fractured EVA, POE, TPO-F and TPO-UV laminates confirmed carboxylic acid signatures of various depth, no carboxylic acid residues have been detected on the fractured TPO-3.5 floor,” the crew acknowledged.

In addition, TPO-3.5 has a “decrease soften move index”, which interprets to a “increased common molar mass” in comparison with TPO-F and TPO-UV. “For crosslinked EVA and POE, the check temperature is already throughout the melting vary of the non-crosslinked, polyethylene wealthy section of those peroxide crosslinked encapsulants,” the lecturers identified.

The crew concluded that the “obtained outcomes clearly present that particular consideration must be given to TPO-3.5 encapsulants for double-glass PV modules” in future analysis. “The subsequent step is to guage the sequential damp warmth and UV growing old of TPO-glass laminates on the long-term efficiency,” Tiefenthaler stated, including that the optimistic findings are on the specimen stage. must be validated and investigated by rising the PV module sizes.

The outcomes of the analysis are introduced in “Effect of UV growing old on debonding of double glass laminates primarily based on totally different crosslinking and thermoplastic PV encapsulants,” which was revealed by Solar power supplies and photo voltaic cells. Researchers from Johannes Kepler University Linz, Christian Doppler Laboratory for Superimposed Mechanical-Environmental Aging of Polymeric Hybrid Laminates, and Borealis.

Last 12 months, one other analysis group on the Johannes Kepler University Linz carried out high-damp-heat exams on double-glass photo voltaic modules made with UV-transparent EVA and POE encapsulants for greater than 10,000 hours, discovering and lots of benefits of utilizing POE encapsulants in comparison with EVA supplies.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.

[ad_2]

Source link