[ad_1]

A analysis group in Australia used a lamination method generally known as chilly isostatic urgent (CIP) to construct a perovksite photo voltaic cell based mostly on a versatile bilayer electrode manufactured from carbon and silver that’s reported to compete with gold-carbon eletrode based mostly counterparts when it comes to effectivity. . and power.

A bunch of researchers led by CSIRO Manufacturing, which is a part of the Commonwealth Scientific and Industrial Research Organization (CSIRO) in Australia used a lamination method generally known as chilly isostatic urgent (CIP) to create a perovskite photo voltaic cell that makes use of a versatile bilayer. electrode manufactured from carbon and coated with silver (Ag).

CIP is usually used to compress several types of powders for forming elements and semi-finished elements. It applies isostatic stress to a powder pattern in all instructions and is thought produce high-integrity semi-finished merchandise that present little distortion or cracking when fired.

“CIP includes immersing a pattern right into a chamber of ambient-temperature fluid, whether or not liquid or fuel, which is then isostatically pressurized,” the scientists defined. “The CIP lamination method has been proven to make use of very excessive mechanical stress (as much as 380 MPa) to type a seamless bodily connection between the outlet transport layer (HTL) and carbon movie, with out damaging the machine, which no warmth and no want for added. adjustments within the morphology of the carbon movie.”

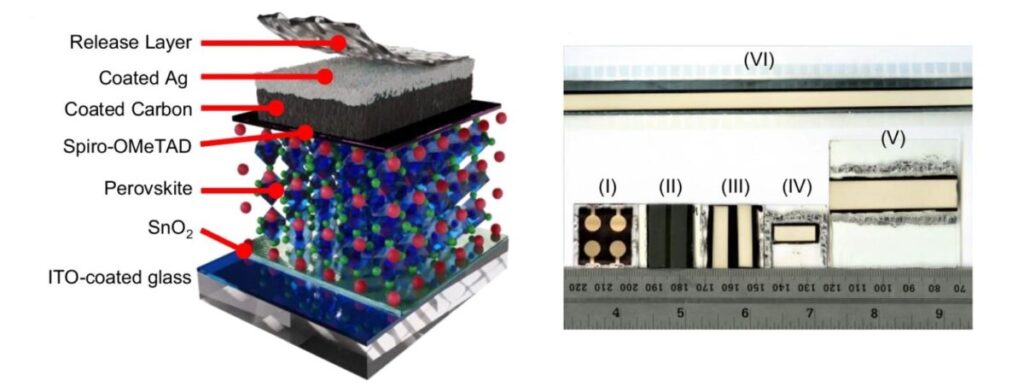

The 60 µm electrode is roofed with a 20 µm silver layer and immersed in water stuffed with CIP chamber on the set stress for 30 s and this course of, in keeping with the analysis group shall be a powerful bond between the carbon layer and the HTL. “When the CIP stress was utilized, the thickness, morphology and conductivity of the coated electrode movies modified,” it defined. “After making use of stress, each movies are compressed, with the Ag movie shrinking to 16 µm and the carbon movie shrinking to 40 µm.”

The teachers constructed the cell with an indium tin oxide (ITO) substrate with a glass coating, an electron transport layer (ETL) based mostly on any tin oxide (SnO2), a perovskite absorber, a HTL counting on Spiro-OMeTAD, and the carbon-silver contact.

Tested below customary lighting circumstances, the machine achieved an influence conversion effectivity of 20.8%, an open-circuit voltage of 1.10 V, a short-circuit present density of 23.2 mA / cm.2, and a fill issue of 81.3%. These outcomes, the scientists say, are per reference gadgets made utilizing costlier, evaporated gold (Au) electrodes.

“Extreme stress is mixed with the advantages of a coated bilayer electrode consisting of carbon for comfortable interface contact and silver for top conductivity,” they additional defined. “Therefore, the lack of efficiency is minimized for giant space carbon perovskite photo voltaic cells, with a report effectivity of 19.8% and 16.9% for cell areas of 0.95 cm.2 and 5.5 cm2each.”

The novel cell design was launched within the paper “A high-pressure isostatic lamination method to manufacture versatile carbon electrode-based perovskite photo voltaic cells,” which was just lately printed in communication supplies. “These findings spotlight the crucial function of the contact interface in enhancing carbon perovskite cell efficiency, and the outcomes pave the best way for the event of low-cost, environment friendly, and dependable perovskite photo voltaic cells,” the researchers concluded.

Another CSIRO analysis group just lately claimed record-breaking effectivity within the manufacturing of absolutely roll-to-roll printed, versatile photo voltaic cells. Researchers say on the time that versatile print photo voltaic cells could possibly be utilized in industries akin to protection, emergency administration, building, agriculture, mining, house exploration and concrete infrastructure.

This content material is protected by copyright and is probably not reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.

[ad_2]

Source link