[ad_1]

Solertix claims to have lowered yield losses in cell-to-module scaling by utilizing an ultranarrow interconnection of 19.5 μm. It additionally states that the proposed interconnection approach can be utilized to realize 30% effectivity in area-matched 4T tandem designs with a perovskite module in a silicon cell.

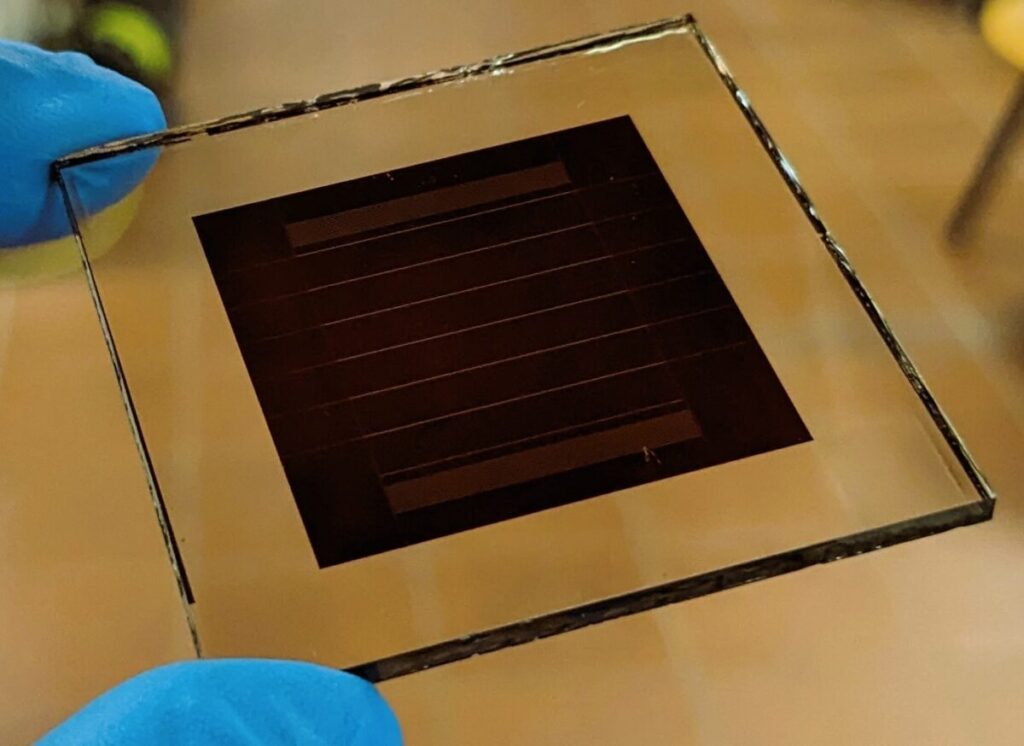

Italian perovskite specialist Solertix, a unit of Italy-based photo voltaic producer FuturaSun, produces mini perovskite photo voltaic panels with an lively floor of two.6 cm2 and an influence conversion effectivity of 20.7%.

“We optimized the laser processes to create the interconnects used to go from the cells to the modules,” stated Solertix CTO, Francesco Di Giacomo. pv journal. “Since the realm used for the interconnects doesn’t present power, we launched a brand new format to attenuate this space with out introducing different sorts of losses. The motive it’s thought-about is the geometrical fill issue (GFF) that describes the ratio between the lively space and the sum of the lively space and interconnects, and we reached a report of virtually 99.6%, whereas within the literature it’s troublesome to transcend 95%.”

In the analysis paper “Over 99.5% Geometrical Fill Factor in Perovskite Solar Minimodules with Advanced Laser Structuring,” written in cooperation with scientists on the University of Rome Tor Vergata, of which Solertix is a spin-off, the Italian startup explains that, when upscaling from perovskite cells to modules, loss could also be as a consequence of layer inhomogeneity loss, P2 ohmic loss, shunts of P1 and P3, and sheet resistance loss.

The so-called P1, P2, and P3 scribes correspond to the three steps of the writing course of for the development of monolithic interconnections that enhance voltages between the cells of the modules. The P1 and P3 steps are aimed toward isolating the again contact layer of neighboring cells and the P2 step creates {an electrical} path between the again contact of 1 cell with the entrance contact of an adjoining one. cell. The P3 step, specifically, is commonly the supply of negative effects reminiscent of again contact delamination, flaking, or poor electrical isolation, as a result of residues that stay within the trench.

The module is constructed with three cells, every with an space of 0.87 cm2. The cells are all designed with a substrate made from glass and indium tin oxide, a hole-transporting materials primarily based on poly(triarylamine) (PTAA), a perovskite absorber, an electron transport layer primarily based on phenyl-C61-butyric acid methyl ester (PCBM), a bathocuproine (BCP) buffer layer, and copper (Cu) steel contact.

“Two rectangular shapes with 1 cm 2 lively space had been designed, with the intention of lowering the resistive loss that happens normally within the TCO electrode: the lively areas are outlined by a P3 scribe, adopted by a P2 scribe to make use of the remaining steel electrode as a present amassing electrode for TCO,” the researchers stated, noting that using the P2-P3 course of enabled the mixing of a present amassing grid utilizing the identical steel layer on the higher electrodes.

The group examined a module constructed with this structure and an ultra-narrow interconnection of 19.5 μm underneath customary illumination circumstances and located that it might probably attain an effectivity of 20.7%, a fill issue of 81.7%, and a geometrical fill issue of 96%, that are unrelated. Resistive loss is detected.

Looking forward, the workforce says it desires to use an undefined superior alignment technique to keep away from attainable module warping throughout processing. “By making use of this novel technique to semitransparent modules made from Solertix, we’re near reaching a 30% effectivity utilizing an area-matched 4T tandem with a perovskite module in a silicon cell,” stated Di Giacomo, with out giving additional particulars.

Solartix was acquired by FuturaSun in June 2023. It was created by the Organic Solar Center (CHOSE), based by Professor Aldo Di Carlo, who additionally assumed the place of president of the scientific committee of the Italian startup.

In March 2021, the University of Rome Tor Vergata introduced a perovskite photo voltaic module with a complete lively space of 42.8 cm2 and an aperture space of 50 cm2. The panel was constructed with 20%-efficient perovskite cells related in 14 collection and was in a position to retain 90% of the preliminary effectivity after 800 hours of thermal stress at 85 levels Celsius.

A number of months in the past, it opened a perovskite photo voltaic module with cells primarily based on triple-cation cesium methylammonium formamidinium (CsMAFA).

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.

[ad_2]

Source link