[ad_1]

In its second month-to-month column for pv journalthe IEC promotes analysis on versatile crystalline silicon photo voltaic cells led by researcher Zhengxin Liu, the Vice Chair of IEC Technical Committee 82, which prepares requirements for photo voltaic PV power techniques.

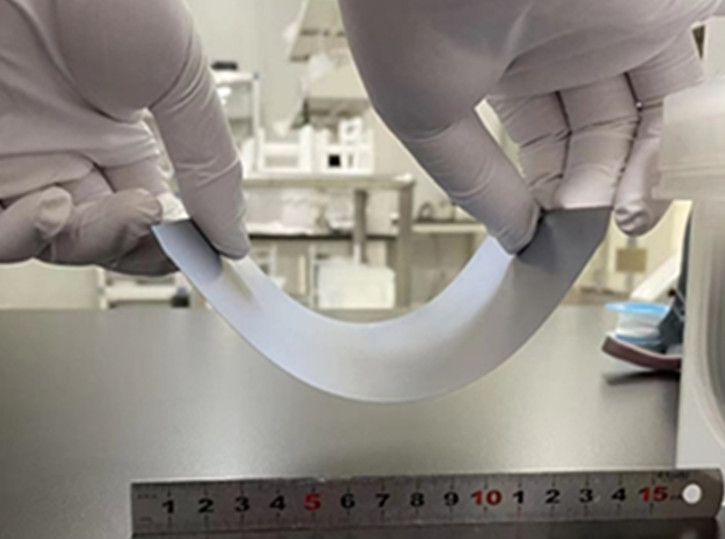

Although crystalline silicon photo voltaic cells have many deserves, together with their materials abundance, excessive energy conversion effectivity and working stability, in addition to their mature manufacturing course of, they’re typically it’s uncared for that it can’t be utilized in versatile purposes, on account of brittleness. traits of crystalline silicon wafers (Fig. 1). For this cause, silicon digital units are sometimes wrapped in onerous glass and/or again sheets to type conventional monofacial or bifacial photovoltaic modules. These modules account for greater than 95% of the present photovoltaic market.

The path to foldable silicon wafers

However, their low power-to-mass ratio hinders their set up on satellites, buildings, autos, clothes, and different curved surfaces. My analysis group has developed a technique to supply foldable silicon wafers with a small bending radius of about 4 mm. When made into light-weight versatile amorphous-crystalline silicon heterojunction photo voltaic cells, the ability conversion effectivity was independently calibrated to be larger than 24% (Fig. 2). When the cells are inserted into a big versatile photo voltaic module (> 10000 cm2), the ability conversion effectivity reaches 22.8%, a lot increased than different versatile counterparts produced from efficient supplies at value.

Compared to straightforward bifacial modules embedded in glass, the weight-to-power ratio of versatile bifacial modules on this analysis is lowered by about 95%, which can pave the way in which for a big self-powered digital market within the close to future.

Image: IEC

Image: IEC

Long-term stability is a matter

For versatile purposes, shut consideration must be targeted on their long-term stability. For instance, microcracks are induced throughout module encapsulation. A extra detailed examination reveals that these microcracks are situated on the endpoints of the solder strips (that are situated on the edges of the machine). This means that the utmost compressive stress is utilized when the endpoint of the solder strips and the floor of the machine are in touch. This was verified by a finite component evaluation utilizing COMSOL Multiphysics software program. Our analysis crew proposed to blunt the pyramids on the perimeters of the wafer, and convert the sharp V-shape channels into rounded U-shape channels between the floor pyramids. By spreading the stress, this technique reduces the utmost stress by virtually an order, which permits the photo voltaic cells to be extra proof against wafer deformation and fixed vibrations. The bending radius of an M2-size cell (156 × 156 mm) is lower than 8 mm. When encapsulated into giant modules of greater than 2 m2, they are often rolled in an identical technique to thin-film modules produced from a-Si, organics, CIGS, CdTe and perovskite (Fig. 3). The minimal crucial bending radius is lower than 5 cm, indicating that it’s appropriate for a lot of area of interest purposes. In addition, these versatile photo voltaic cells are free-standing units, in contrast to different thin-film cells deposited on costly natural substrates or chrome steel.

The analysis group reveals purposes for lengthy autos between the peak of 10-100 km. In this vary, area radiation from ultraviolet rays and high-energy particles is much less of a problem. More experiments must be carried out to estimate the impact of extra excessive duties earlier than future deployment.

Image: IEC

Standards and testing are required

In this research, the analysis crew additionally famous that there are not any detailed check requirements for versatile silicon photovoltaic modules. IEC Technical Committee 82, which prepares requirements for photo voltaic PV power techniques, can lead the work on this area. An experimental setup for the vibration checks has not but been decided. The parameters for the bending checks embrace the bending radius and period, and different check strategies might embrace electroluminescence, photoluminescence, present voltage evaluation and so forth. Finally, pressure impact checks are beneficial, for the reason that tensile drive utilized might lead to failures of the encapsulant, and destroy the conformal contacts between the encapsulant and the cell floor, in addition to the conformal contacts between the solder strips and the cell floor.

Zhengxin Liu is an knowledgeable in photo voltaic cell supplies and measurement units and know-how for photo voltaic cells. His present analysis pursuits embrace high-efficiency crystalline silicon photo voltaic cells, physics of heterojunction constructions, in addition to the standardization of photo voltaic cells. He introduced a abstract of his analysis crew’s breakthrough paper on versatile crystalline silicon photo voltaic cells, which was first revealed within the journal NATURE.

The International Electrotechnical Commission (IEC) is a worldwide, non-profit membership group that unites 174 international locations and coordinates the work of 30,000 specialists worldwide. IEC International Standards and conformity evaluation assist worldwide commerce in electrical and digital items. They facilitate entry to electrical energy and confirm the security, efficiency and interoperability {of electrical} and digital units and techniques, together with for instance, shopper units akin to cellphones or fridges, workplace and medical gear, info know-how, energy technology, and extra.

The views and opinions expressed on this article are these of the writer, and don’t essentially mirror these held by pv journal.

This content material is protected by copyright and might not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: editors@pv-magazine.com.

[ad_2]

Source link