[ad_1]

From pv journal India

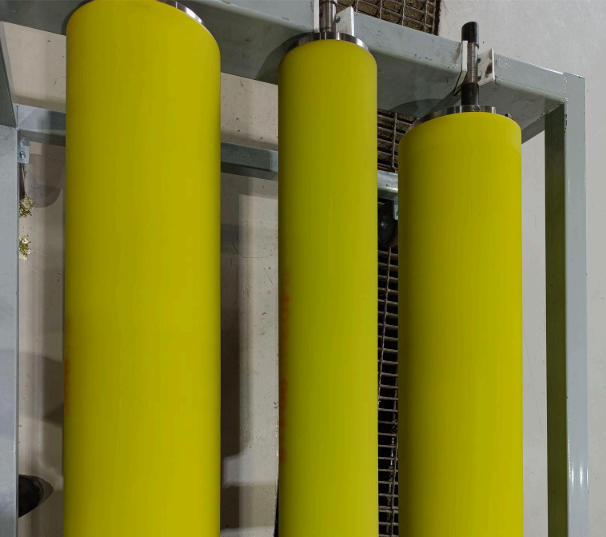

UIS Technologies, a precision expertise firm based mostly in Penang, Malaysia, introduced the commissioning of its PU recoating and regrooving options for WGRs at Adani’s 2 GW photo voltaic ingot-wafer facility in Mundra, Gujarat, India.

WGRs play an essential position within the ingot slicing stage of silicon ingot-to-wafer manufacturing processes. The exact grooving of those rollers vastly impacts the form and thickness of the silicon wafers, even small deviations probably affecting photo voltaic cell effectivity. Due to the continual nature of this course of, put on and tear will lead to deterioration of the accuracy of the grooving enamel and the pitch of the WGR over time.

Manufacturers are confronted with the selection of investing in new WGRs or choosing recoating and regrooving to increase their life. UIS Technologies provides a turnkey answer for the recoating and reprocessing of WGRs on the plant website with a whole switch of data to plant engineers, in order that they will independently use the answer in the long term . This means no costly abroad journey of apparatus.

UIS Technologies has been offering these options to international silicon wafer producers for a very long time.

“PU recoating and regrooving can preserve optimum efficiency for as much as eight to 10 years,” mentioned CT Teh, managing director of UIS Technologies. “After every regrooving course of, WGRs could make 80 to 120 cuts, relying on the chopping velocity of the plant.”

This content material is protected by copyright and will not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link