[ad_1]

The French analysis institute offered in a scientific paper the technical particulars of its recyclable heterojunction module with an influence output of 566 W and a carbon footprint of solely 313 kgCO2eq/kW.

Researchers at France’s National Solar Energy Institute (INES) – a division of the French Alternative Energies and Atomic Energy Commission (CEA) – revealed a paper describing the technical options of the industrial-scale prototype of a silicon heterojunction (SHJ) module introduced earlier final yr.

“The paper explains all of the technical particulars and complementary outcomes,” the corresponding writer, Timea Béjat, stated pv journal, famous that the workforce used an inner ECO PV instrument for Life Cycle Assessment (LCA) research to optimize PV module design for low environmental impression. Béjat additionally identified that an vital results of the analysis is that the bottom carbon designs could be achieved with the applied sciences obtainable at this time.

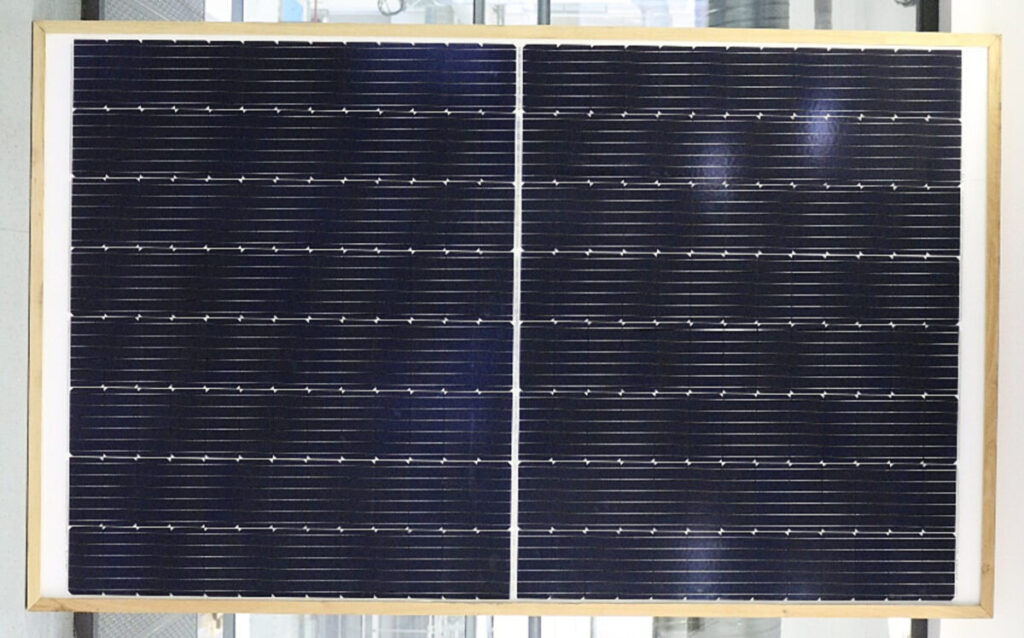

The scientists constructed the panel through the use of the CEA-INES pilot line. They used 130-μm M2 Czochralski wafers, vapor deposition, and clear conductive oxide on either side of a 6-busbar design cured at 200 C for quarter-hour. The cell bifaciality issue is within the vary of 92%, the workforce stated.

“For a normal PV module, we recognized the principle growth steps to scale back its environmental footprint,” the analysis workforce stated. “This led us to cope with the parts which have the best impression on the carbon footprint, specifically the wafer, glass entrance sheet and aluminum body.”

At the mobile degree, the teachers lowered the thickness of the wafers, which they claimed had been obtained by way of “the European worth chain.” Metallization and cell interconnection are optimized to scale back silver consumption. At the module degree, the thickness of the glass is lowered, and the standard aluminum framing is changed by a wooden wrapped in a glass backsheet configuration.

“Furthermore, we utilized a ‘design for recycling’ strategy for the choice of encapsulant and backsheet,” stated the workforce. “The mixture of those improvements led us to the belief of a 566-W recyclable module utilizing tiling interconnection, cells with a mean effectivity of twenty-two.57% with a carbon footprint of 313 kgCO.2eq/kWp.”

The prototype’s reported carbon footprint of 313 kgCO2 eq/kW is best than present modules, which the workforce says varies between 700 kgCO2eq/kWp and 800 kgCO2eq/kWp.

Supposedly, that is additionally decrease than merchandise from “pioneer producers” that obtain sub-450 kgCO2eq/kWp modules, similar to Korea’s Qcells, Belgium’s Bisol, Singapore’s REC, and Chinese producers JinkoSolar, Trina Solar and Huasun, as introduced by the analysis workforce in an incomplete listing.

Regarding the bill-of-materials, the group stated it requires a “design for recycle” strategy, which suggests selecting a thermoplastic encapsulant, fluorine-free backsheet, and skinny entrance glass. In addition, the usage of a timber body as an alternative of aluminum lowered the carbon footprint by greater than 50-60 kgCO2eq/kWp, the researchers famous, however in addition they emphasised that the complete qualification of any such framing that materials is incomplete.

The workforce concluded that by optimizing the technical parameters and selecting environmentally pleasant supplies, it “can create an eco-designed PV module with a really low carbon footprint,” and it reveals the significance of discovering a compromise between environmental impression optimization and module efficiency. and sturdiness.

Future work will try to enhance efficiency and cut back materials consumption, similar to silver, on the cell and module degree, in addition to combine recycled materials content material in any respect phases of the worth chain, in keeping with the workforce. . The workforce additionally plans to analyze various backsheet supplies with out aluminum and fluorine supplies and to work on establishing the reliability of different framing supplies.

The “Design for the surroundings: SHJ module with ultra-low carbon footprint” examine was not too long ago revealed in Advances in Photovoltaics.

This content material is protected by copyright and is probably not reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: editors@pv-magazine.com.

[ad_2]

Source link