Chinese researchers have developed a mannequin to foretell the lifetimes of heterojunction (HJT) modules made with an ultraviolet cut-off polyolefin elastomer (POE) encapsulant. The methodology takes into consideration elements comparable to temperature, humidity and UV irradiation.

To handle issues about heterojunction photo voltaic module degradation, a bunch of scientists led by the Chinese Academy of Sciences, developed a mannequin to foretell the lives of heterojunction modules.

The mannequin takes into consideration elements comparable to temperature, humidity and UV irradiation and is utilized by the analysis workforce to foretell the lifetime of modules made with ultraviolet cut-off POE encapsulant movies.

The scientists emphasised that the deterioration attributable to ultraviolet in heterojunction panels is “primarily because of the discount of short-circuit present” and that it may be “successfully prevented” by utilizing encapsulants made from POE, as a result of because it has sturdiness properties.

The group examined its methodology on heterojunction modules made from a double configuration of glass and 144 items of half-cut M2-sized cells. One set of panels is laminated with ultraviolet passive POE (UVP) encapsulant and the opposite set is laminated with ultraviolet cut-off POE (UVC) encapsulant.

The samples had been uncovered to accelerated UV irradiation assessments from 60 kWh to 300 kWh within the ultraviolet chambers of the National Center of Inspection of Solar Photovoltaic Products Quality of China.

Modeling and UV assessments have enabled the workforce to attract some early conclusions. “In common, UVC modules have an extended life than UVP modules, which may be prolonged to a mean of 4.2 years in numerous areas. This benefit is principally because of the UV cut-off POE , which blocks UV photons’ harm to HJT photo voltaic cells,” the lecturers stated.

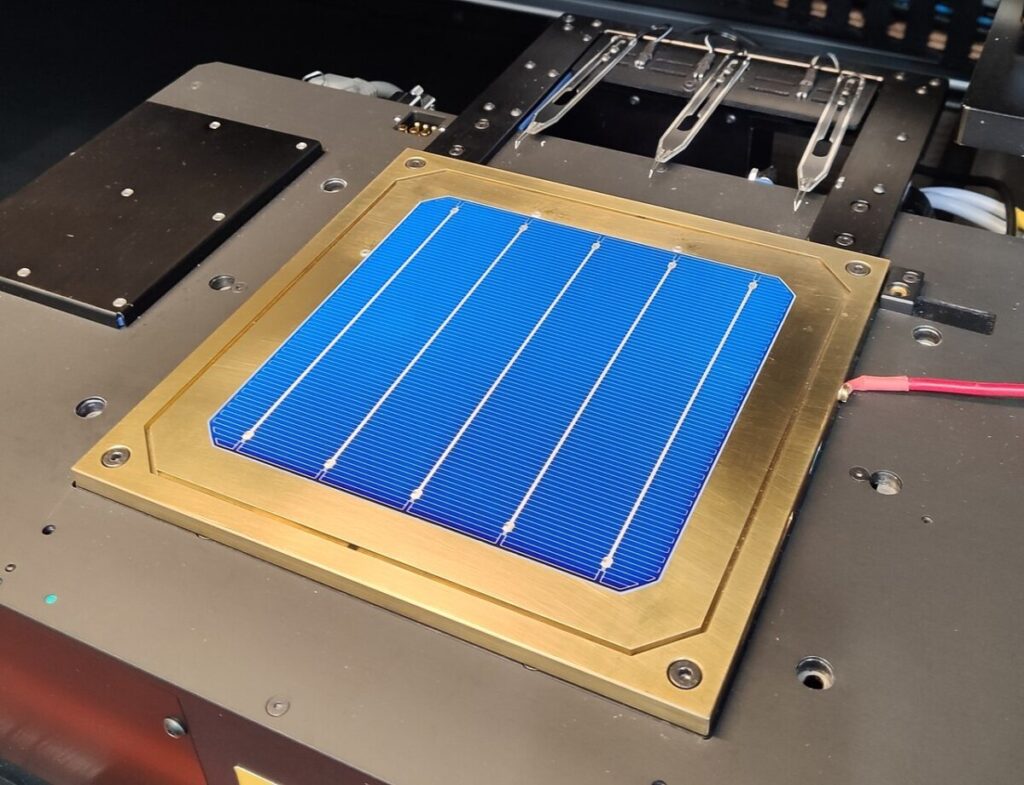

Because temperature and humidity additionally have an effect on the module degradation price and the workforce didn’t need to rely solely on UV knowledge, it performed a sequence of damp warmth (DH) assessments carried out solely on the UVC encapsulant materials. The mini modules are made with an M2 measurement HJT cell in a double glass insert and laminated with UVC movies.

Fifteen samples of single cell mini-modules had been ready. They had been divided into three teams uncovered to damp warmth situations as follows: 85 C at 85% relative humidity, 55 C at 85% relative humidity, and 25 C at 85% relative humidity.

All mini-modules had been then subjected to damp warmth (DH) situations for 500 h, and the current-voltage output parameters had been measured each 50 h beneath customary take a look at situations of irradiation at 1,000 W./m2 at 25 C.

Next, the workforce used the mannequin to make degradation predictions about HJT modules based mostly on particular local weather parameters for 5 areas throughout China similar to totally different local weather zones – Daqing, Hainan, Qinghai, Ningxia, and Shanghai.

The evaluation exhibits that the methods situated in Daqing and Ningxia can obtain lifetimes of greater than 30 years, as a result of these areas have low UV irradiation of 48 kWh/m2 and low humidity, lower than 55%.

“Apparently, the lifetime of HJT modules may be simply calculated when temperature, humidity and irradiation knowledge from a particular location are enter into the Peck mannequin,” the workforce concluded.

Details of the analysis may be present in “Predicting the lifetime of HJT modules in the direction of outside real-world environments,” which was not too long ago revealed in Solar Energy Materials and Solar Cells.

Researchers collaborating within the research are from China’s State Key Laboratory of Materials for Integrated Circuits, University of Chinese Academy of Sciences, Tongwei Solar, Huaneng Clean Energy Research Institute, and Huaneng Gansu Energy Development.

This content material is protected by copyright and might not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: editors@pv-magazine.com.