[ad_1]

The transition from lab-scale spin-coating to completely R2R coated perovskite photo voltaic cells requires a coating approach that’s not solely suitable with inline R2R processes but additionally results in the manufacturing of environment friendly photo voltaic cells. The slot-die coating stands out for its versatility in S2S and R2R processes, which permits the optimization of every layer initially on a S2S foundation earlier than shifting to R2R. This methodology is crucial for R2R manufacturing due to its distinctive course of management and flexibility. It presents exact management of coating thickness and high quality and makes use of a visco-capillary mannequin to foretell meniscus power and movie uniformity, considering the traits of the previous answer corresponding to viscosity, floor stress, and density, together with coating parameters corresponding to shim design, meniscus size. , coating velocity and drying course of. This precision ensures all layers are of constant high quality, important for attaining high-efficiency cells, making the R2R slot-die coating the first alternative for environment friendly and scalable photo voltaic cells. cell in steady manufacturing.11,12. However, most analysis on R2R-coated perovskite photo voltaic cells makes use of vacuum evaporation for the highest electrode, with some makes an attempt at answer processing, which is incompatible with R2R resulting from time constraints, value and excessive temperature. not appropriate for versatile substrates.13.

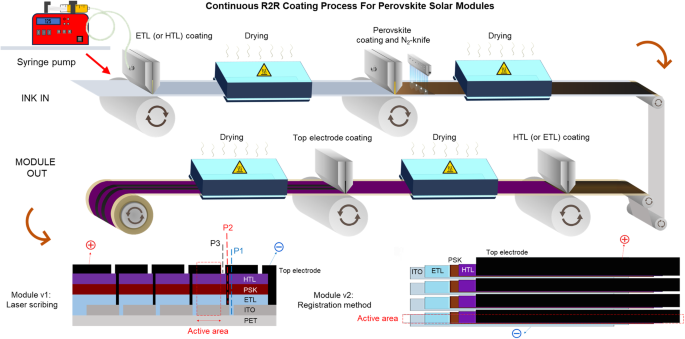

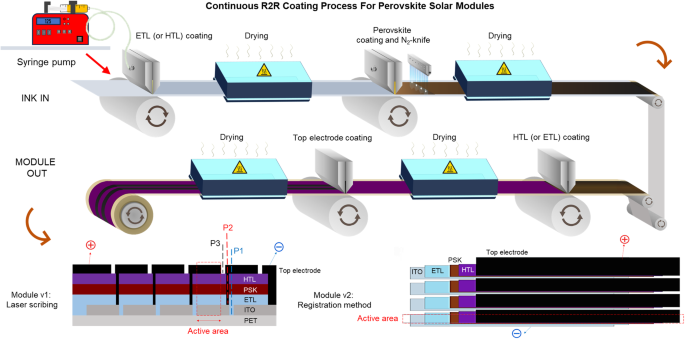

Fortunately, current breakthroughs have efficiently transitioned perovskite photo voltaic cell manufacturing from partially R2R coating / partially vacuum-processed prime electrodes to a totally R2R coated course of, utilizing carbon for the highest electrode, bypassing costly metals corresponding to gold or silver, and enhancing scalability and sustainability. inline steady photo voltaic manufacturing. Figure 1 reveals a schematic of your entire R2R coating course of for perovskite photo voltaic modules. The schematic illustrates how two completely different variations of the module might be achieved by way of the R2R coating approach. The first model required laser patterning to determine P1, P2, and P3 inside the module. In distinction, the second model eliminates the necessity for laser or mechanical writing—not together with the patterning of the ITO substrate—and as an alternative depends on the strategic alignment of the strips to create the perovskite module.

In the laser scribing methodology, an R2R coater outfitted with a laser exactly writes the clear conductive oxide (P1), the underside layer of perovskite (P2), and the highest electrode (P3) to offer the mandatory connections. In distinction, the registration methodology makes use of strip-coating, with every layer rigorously aligned utilizing a registration system to make sure correct placement and connections. This methodology requires an elaborate design to attain the very best doable geometrical fill issue, which presents a higher problem in comparison with laser patterning. PET Polyethylene terephthalate, ITO Indium tin oxide, N2 Nitrogen, PSK perovskite, ETL electron transporting layer, HTL gap transporting layer.

Our workforce has achieved a milestone by producing the world’s first all-perovskite photo voltaic cell beneath ambient room circumstances in open house, with a PCE of 10.8%14. This work enabled using all layers, together with the highest electrode, by utilizing carbon ink obtained from low cost and low toxicity solvents for slot-die R2R coating. Although carbon might not naturally surpass {the electrical} conductivity of conventional supplies corresponding to gold, it presents a aggressive different by putting a steadiness between conductivity, cost-effectiveness, and environmental sustainability. This steadiness is additional enhanced by carbon’s chemical stability, moisture resistance, and mechanical power, which collectively enhance the steadiness and efficiency of photo voltaic cells, inserting carbon as a viable assist possibility. within the pursuit of targets in superior photovoltaics.

Groundbreaking work by Weerasinghe et al. additional improved the sphere by shifting from single-strip cells to multi-strip modules. They used gravure, slot-die and display screen printing R2R coatings to create the primary good R2R perovskite modules, attaining a PCE of 15.5% for particular person cells and 11% for serially interconnected.15. They report the profitable switch from R2R perovskite cells to modules, utilizing optimized fabrication parameters to provide large-area modules. Using a mixture of R2R techniques—gravure for ETL and carbon prime electrode, slot-die for perovskite and HTL, and display screen printing to make use of clear silver for charge-collection grids—they effectively produced perovskite modules with built-in charge-collection capabilities. .

They tackled the numerous technical challenges of R2R coating for perovskite units by introducing the Printing Friendly Slot-Die (PFSD) coating methodology beneath ambient air. This innovation improves the standard of the perovskite layer by way of precursor optimizations and thru using edge-blowing strategies, making certain fast conversion of the specified construction appropriate for R2R time constraints and attaining uniform coatings. at a big size. Edge blowing not solely improves perovskite high quality and system reliability but additionally improves humidity resistance, making PFSD a viable methodology for cost-effective manufacturing. Solving the problem of high-volume manufacturing, they applied a programmable R2R slot-die coater for automated operation, enabling the each day manufacturing of 1000’s of distinctive perovskite cells. Recognizing the impracticality of guide characterization at this scale, they launched an automatic R2R tester able to evaluating over ten thousand cells per day, with system parameters calculated and recorded on-line for fast evaluation. This new methodology permits for the fast optimization of vacuum-free perovskite units by effectively exploring a variety of producing parameters, ensuing within the highest doable efficiency of their might be achieved in a shorter timeframe. Additionally, their value mannequin estimated manufacturing prices for perovskite photo voltaic cells to be decrease than conventional strategies however nonetheless larger than mass-produced silicon photo voltaic cells priced under $0.30 per watt. However, with their estimate placing perovskite photo voltaic cells at $0.7 per watt, additional reductions are wanted for the know-how to attain widespread affordability and large-scale commercialization.

While recognizing their commendable achievements, particularly within the growth of low-cost, environment friendly, absolutely R2R-coated perovskite modules, there is a chance to additional look at a side crucial to the expansion of perovskite units: issues within the atmosphere. While they use non-toxic deionized DI water for ETL, the solvents utilized in different components of the method are extremely poisonous, with some having strict publicity limits in open areas. Specifically, dimethylformamide DMF was used for the perovskite layer, and chlorobenzene and dichlorobenzene have been used for the HTLs. This raises necessary security and environmental points that have to be addressed to make sure the sustainable growth and business viability of perovskite photo voltaic cell know-how.

[ad_2]

Source link