[ad_1]

US researchers on the Department of Energy’s National Renewable Energy Laboratory used a round financial system framework to find out find out how to scale, deploy, and design metallic halide perovskite photo voltaic panels to be simply recycled sooner or later.

Researchers on the US Department of Energy’s National Renewable Energy Laboratory (NREL) used a round financial system framework to find out find out how to scale, deploy, and design future metallic halide perovskite photo voltaic panels to be simply recycled.

As initiatives to commercialize metallic halide perovskite (MHP) photo voltaic expertise proceed, particularly efforts to make sure sturdy subject efficiency, NREL researchers have begun a examine of the sustainability design components as an vital side of commercialization.

“Our function on this perspective paper is to level out that the prevailing expertise doesn’t primarily produce merchandise with sustainability and circularity ahead. It is just not particularly designed to reduce waste or use the bottom vitality processing steps,” Joey Luther, the corresponding creator of the analysis, mentioned. pv journal. “However, since PV is a sustainable expertise, now could be the time to begin evaluating how we are able to develop the commercialization of MHPs with sustainability in thoughts.”

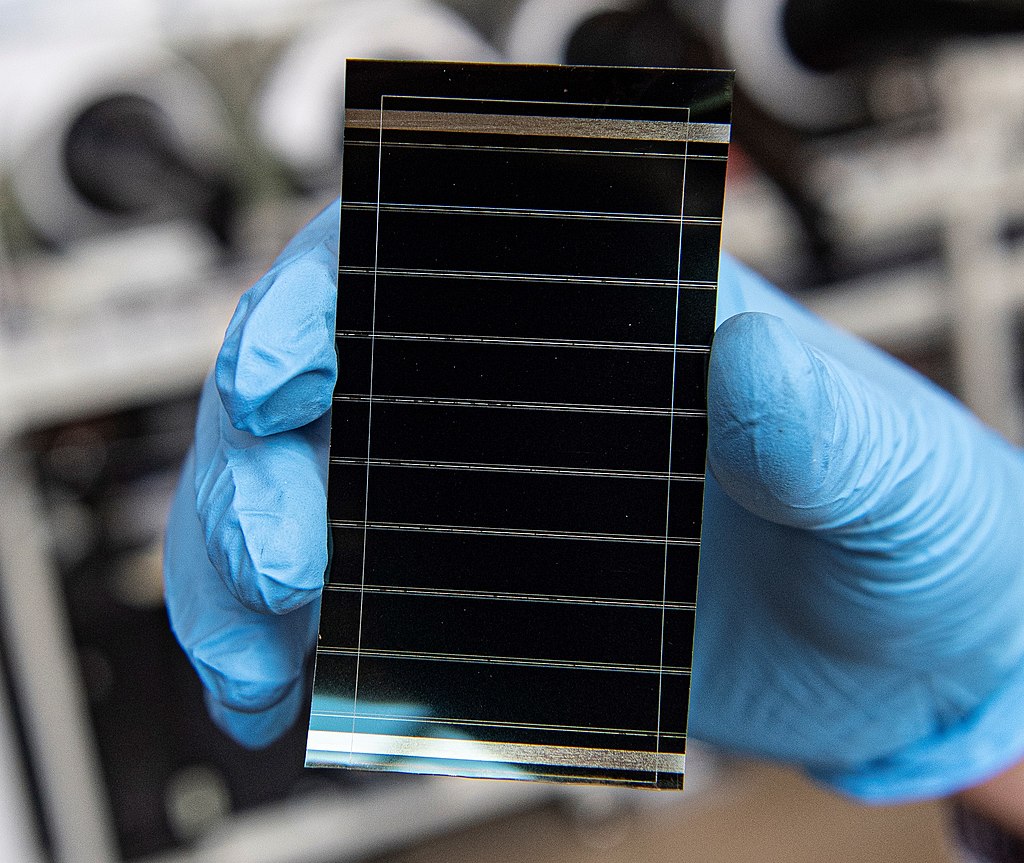

The group made the analysis based mostly on aa prototypical single-junction MHP module near industrial designs, framed with mounting rails in a glass-glass module configuration with polymer encapsulants, and edge sealing typical of silicon and cadmium telluride panels. Individual PV cells are built-in by writing, and embody a entrance glass coated with a clear conductor, the MHP layer sandwiched between electron and gap transport supplies and a again electrode.

In addition, the staff studied the chemical parts, molecules, and supplies generally utilized in perovskite A, B, and X websites.

For all the above, features of sustainability are analyzed, corresponding to vitality effectivity, carbon depth, uncommon mineral mining, recycling, soil abundance, value, fossil gasoline sources, unsafe encapsulation, well being hazards, and flammability and so on.

The prototype was additional evaluated based mostly on important materials considerations, embodied vitality, carbon impacts and round provide chain processes. The evaluation consists of the body, rail supplies, back and front glass, encapsulation polymers, solvents, electron and gap transport supplies, and electrode supplies.

In a desk full of knowledge, the staff particulars how the eleven “Rs” of circularity for photovoltaics can present alternatives and benefits inside sustainable manufacturing. An adaptation of the idea “scale back, reuse, recycle”, a number of the Rs mentioned are listed right here: rejection of fossil fuels and carbon-intensive supplies; scale back vitality, materials, and carbon enter, restore or design for restore, reuse, repower, restoration, and vitality restoration.

When it involves recycling, the researchers be aware that ‘recycling’ includes downcycling into decrease worth, or decrease high quality, merchandise. They defined that recycling is beneficial when recovered feedstocks substitute virgin supplies, which require intensive refining. There is room for enchancment. For instance, the manufacturing of PV glass nonetheless makes use of the virgin origin of latest PV glass merchandise and never post-consumer PV glass cullet, they mentioned.

The staff recognized 5 key areas and alternatives to pursue. The first is to enhance MHP module reliability to satisfy present industrial PV lifetime requirements. Second, look at the availability chain of low-trade-volume uncooked supplies, corresponding to cesium, and guarantee ample accessibility for the sustainable enhance of a given composition of MHP, or focus analysis, to scale back or substitute . Third, discover alternate options to indium. Fourth, discover find out how to facilitate PV glass recycling with out downcycling. And fifth, additional improvement of the module remanufacturing course of.

“An affordable mixture of those options will allow MHP-PVs to contribute meaningfully and sustainably to the vitality transition,” the staff emphasised.

The scientists acknowledged that “circulating the PV provide chain, particularly by way of recycling and remanufacturing glass”, supplies alternatives to scale back vitality and carbon in MHP-PVs. “Improvements in lifetime and reliability stay an important for the vitality transition and supply the best advantages,” they concluded.

The view is detailed in “Sustainability pathways for perovskite photovoltaics,” revealed in environmental supplies.

This content material is protected by copyright and will not be reused. If you need to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

Popular content material

[ad_2]

Source link