[ad_1]

UK-based startup Futraheat has developed an industrial warmth pump that may be built-in into present manufacturing facility infrastructure to supply high-temperature course of steam.

“Unlike most warmth pumps, which ship scorching water as much as 80 C, the Futraheat warmth pump can produce steam as much as 130 C – important for the manufacturing trade and believed to be a primary for the UK,” a spokesperson from the corporate stated. pv journal. “This too appropriate with PV.”

The Greenanstram system has a warmth provide capability of 300 kW to 1.5 MW and the sink temperature can attain as much as 200 C. The working fluids R1233ZD and steam. Its coefficient of temperature (COP) is as much as 6.2

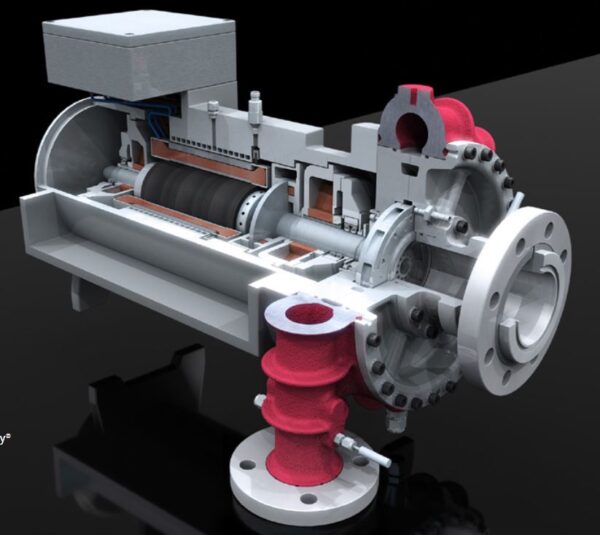

The core of the system is the TurboClaw centrifugal compressor which, in accordance with the producer, operates at lowered velocity.

oil-free, which ends up in decrease manufacturing, working and upkeep prices.

Image: Futraheat

The everlasting electrical magnetic motor has a rated energy of 100 kW and a rotation velocity of 20,000 rpm. “The compressor can elevate the temperature as much as 60 C,” the spokesman stated.

The firm lately deployed a 300 kW prototype within the Hepworth Brewery, based mostly in Sussex, UK. “The The brewery already has photo voltaic panels and that is a part of their plan to make use of them to energy the warmth pump,” stated the spokesperson.

Hepworth Brewery expects the brand new warmth pump to cut back vitality consumption and carbon emissions related to boiling wort by as much as 90%, whereas reducing gas prices by as much as 40%.

The pilot undertaking will be scaled up throughout the location to recuperate virtually all the fossil fuel-generated warmth utilized by the brewery.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].

Popular content material

[ad_2]

Source link